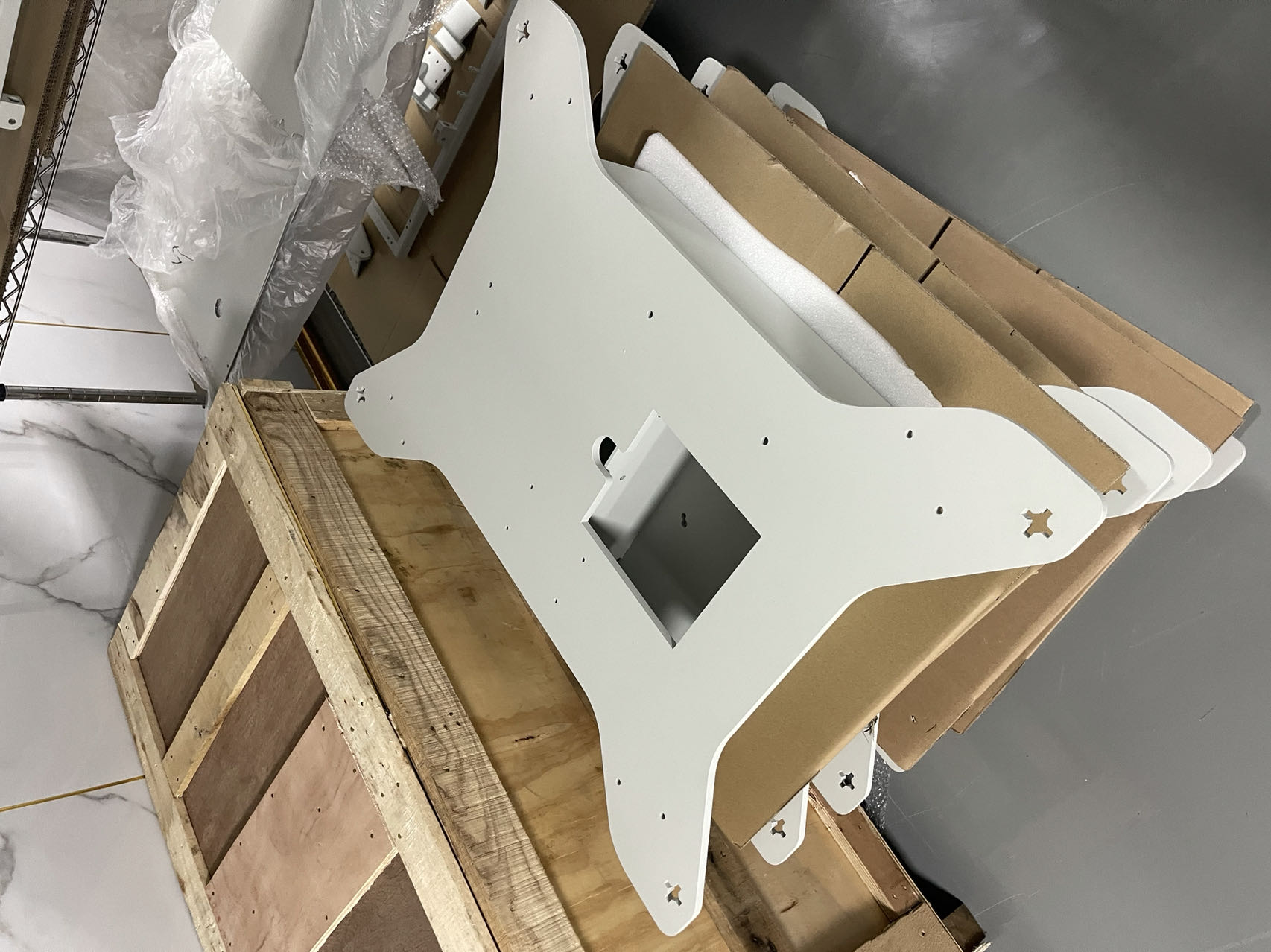

Sheet Metal Prototype

Creating a sheet metal prototype involves the same basic steps as sheet metal fabrication but focuses on producing a small-scale version of the final product for testing, evaluation, and validation purposes.

Material:

Choose the appropriate type and gauge of sheet metal for the prototype based on factors such as the intended application, required strength, and manufacturability.

Cutting:

Use cutting techniques such as laser cutting, water jet cutting, or shearing to cut the sheet metal into the required shapes and sizes according to the design specifications.

Laser cutting is often preferred for its precision and versatility, especially in prototyping.

Bending and Forming:

Utilize press brakes or other forming equipment to bend the metal sheets into the desired shapes and configurations as per the design.

Ensure that the bends are accurate and consistent with the intended prototype.

Finishing:

Apply any necessary surface treatments or finishing processes to the prototype to enhance its appearance, durability, or functionality.

This may include painting, powder coating, anodizing, plating, or polishing, depending on the requirements of the prototype.

Please let us know how we can assist you further. We look forward to the opportunity to work with you.