Zinc Alloy

Zinc alloy die casting and Zinc alloy CNC machining are two different manufacturing processes with distinct differences in production methods and application scenarios.

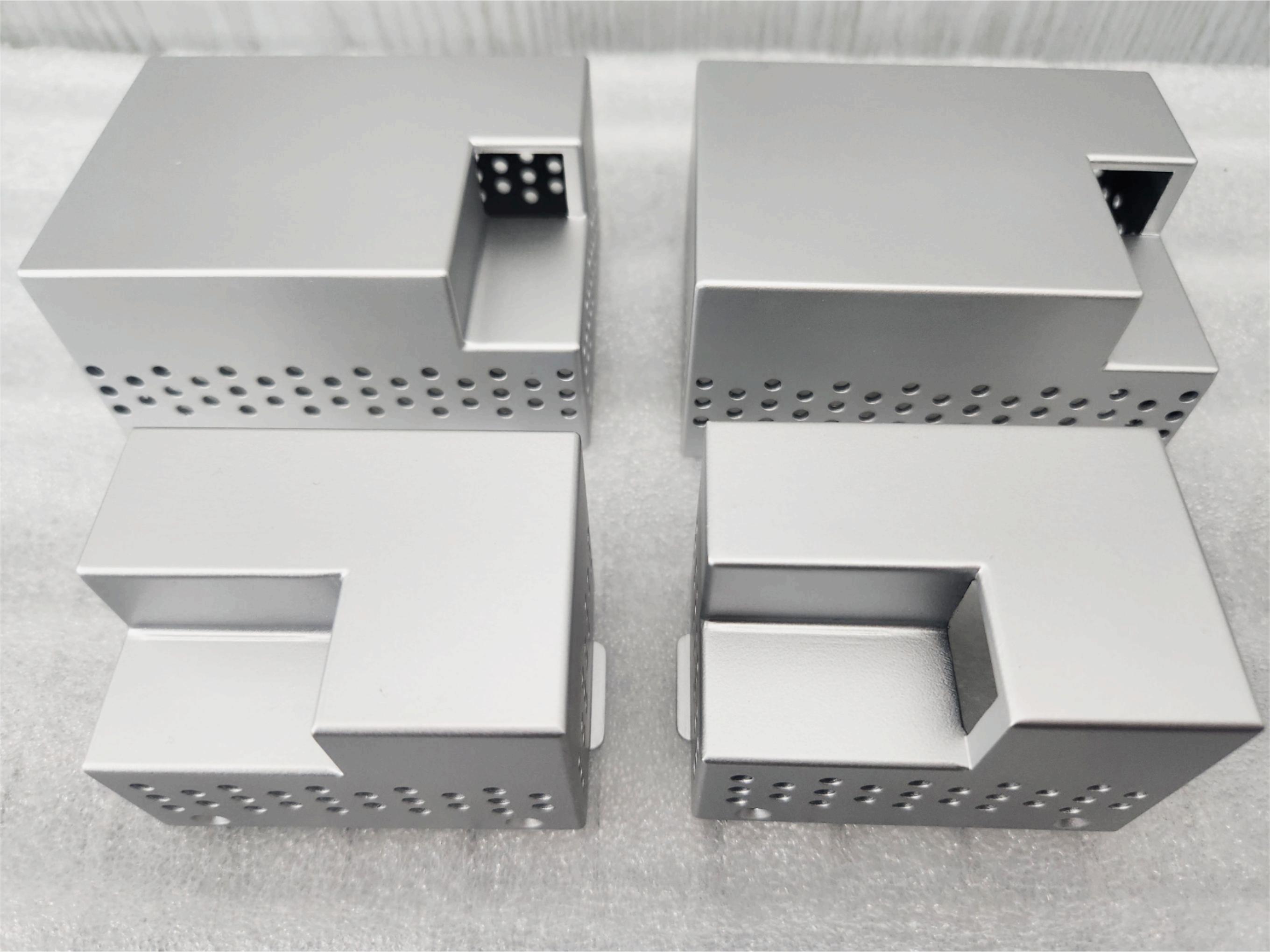

Zinc alloy die casting is a manufacturing method that involves injecting molten zinc alloy into molds for shaping.

This process is suitable for mass production, enabling rapid manufacturing of parts with complex shapes at relatively low costs.

Products produced by die casting typically exhibit high precision and smoothness, although they may be subject to some design limitations.

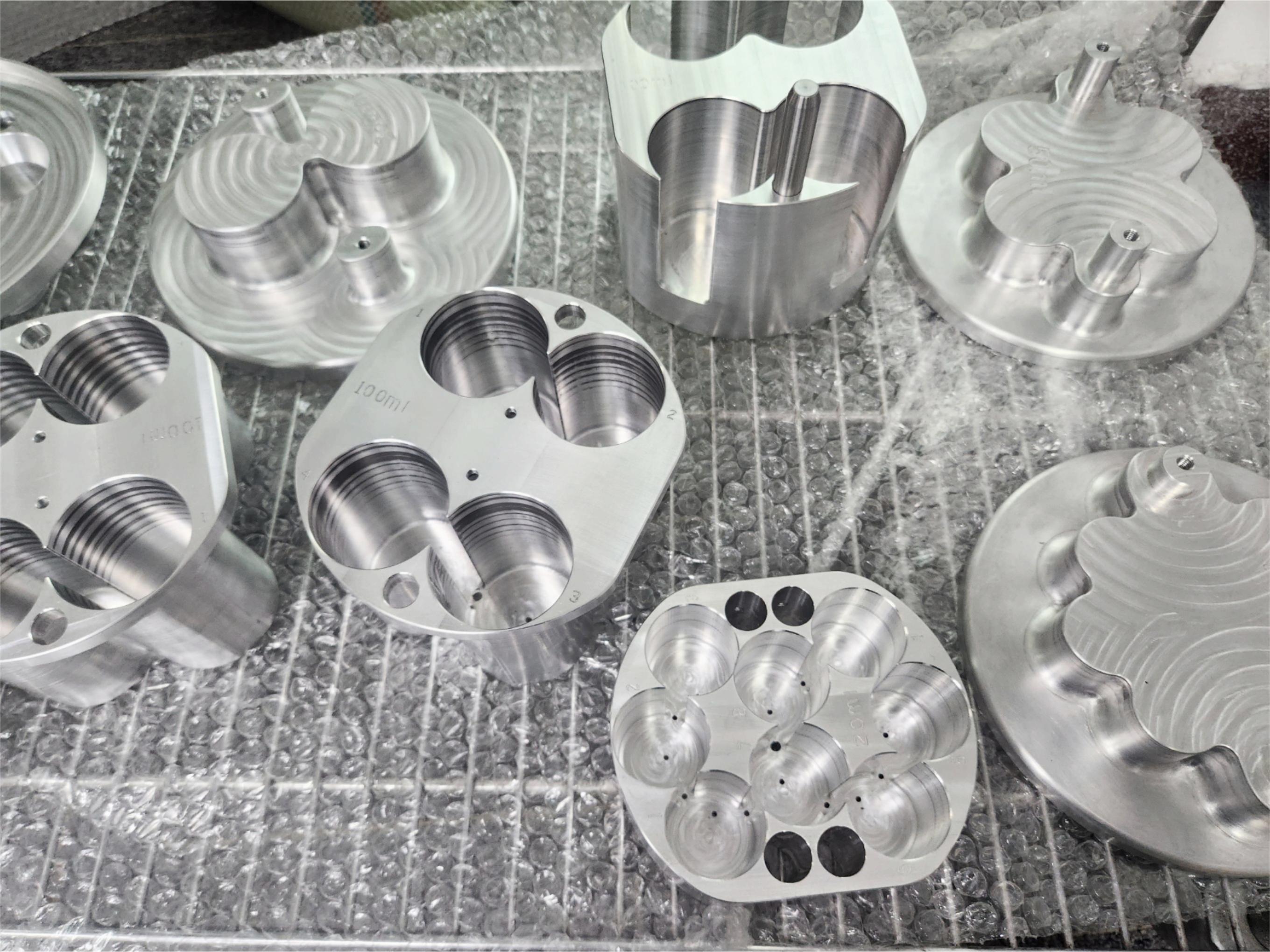

On the other hand, CNC machining is a computer-controlled mechanical machining method.

It utilizes rotating cutting tools to remove material from the workpiece to achieve the desired shape and dimensions.

CNC machining can process various materials, offering high flexibility to manufacture highly complex parts with high precision.

However, CNC machining tends to be relatively expensive and slower in production speed.

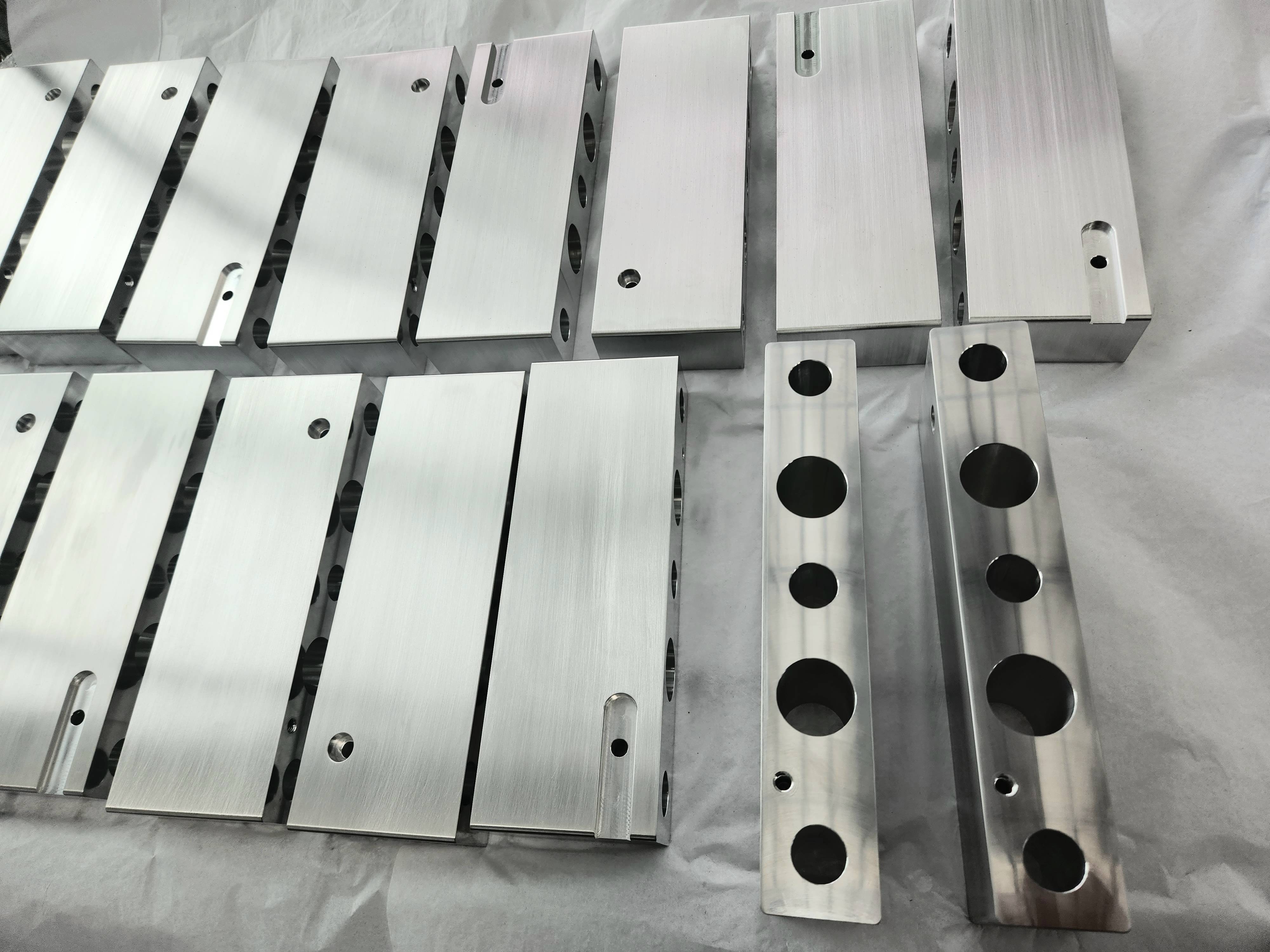

In summary, zinc alloy die casting is suitable for mass-producing simple or moderately complex parts, while CNC machining is more suitable for small-batch production or manufacturing complex, high-precision parts.

The choice between the two processes depends on specific needs and application scenarios.