Aluminum Alloy

Five methods of aluminum alloy processing:

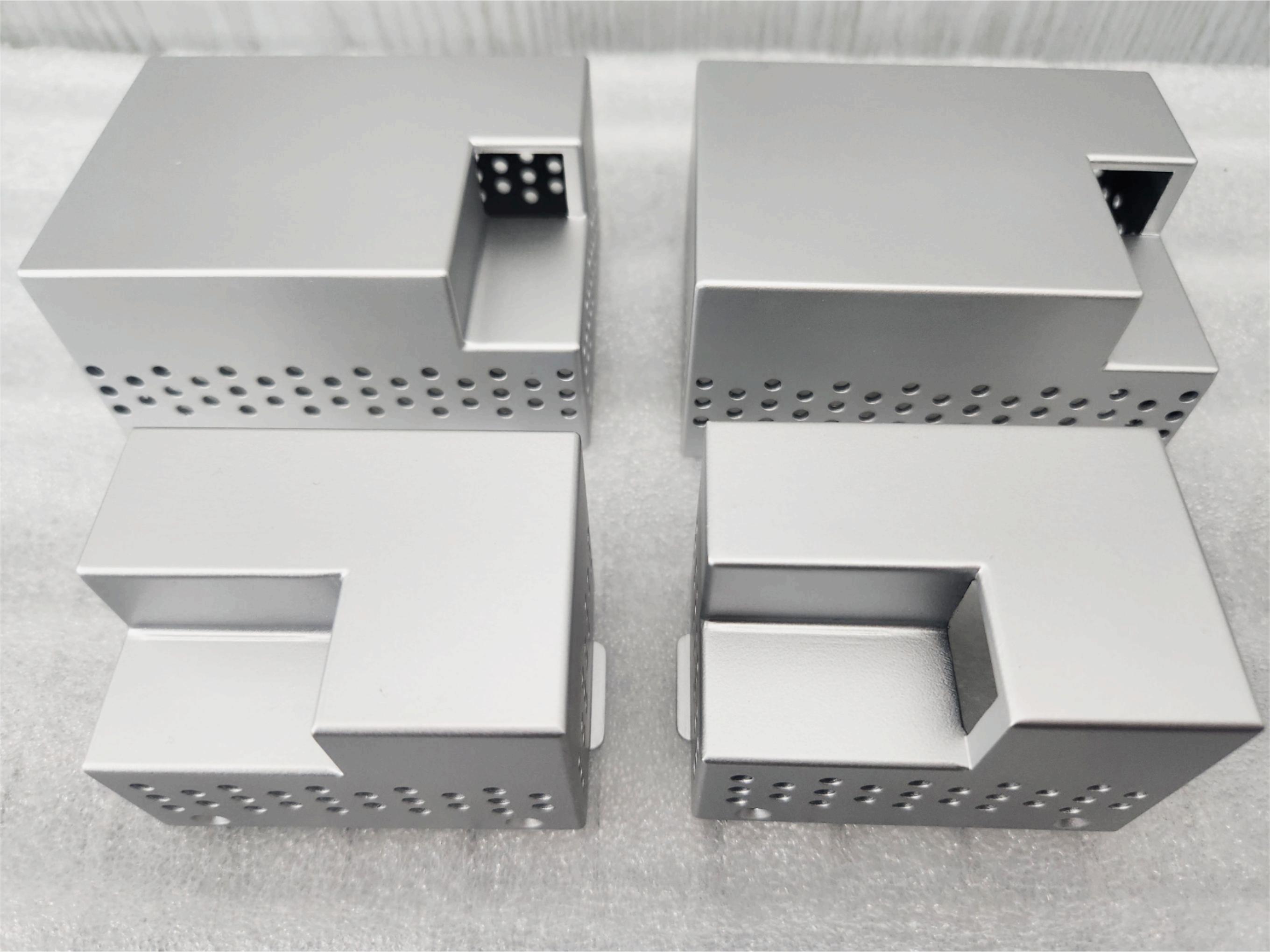

Stamping is a manufacturing process in which force is applied to sheet metal, strip, pipe, and profile materials through presses and dies to produce workpieces with plastic deformation or separation according to the shape and size of the required workpiece.

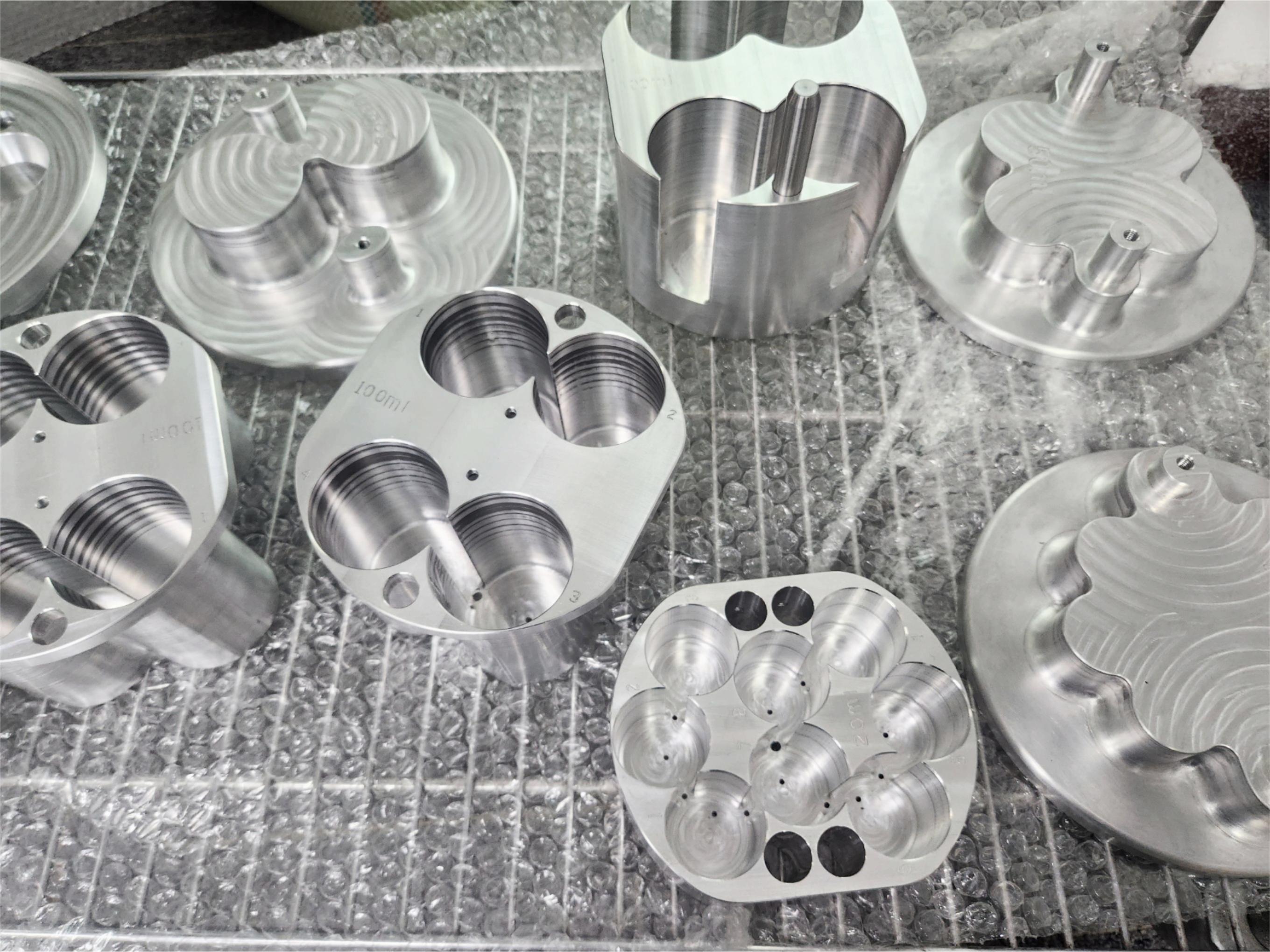

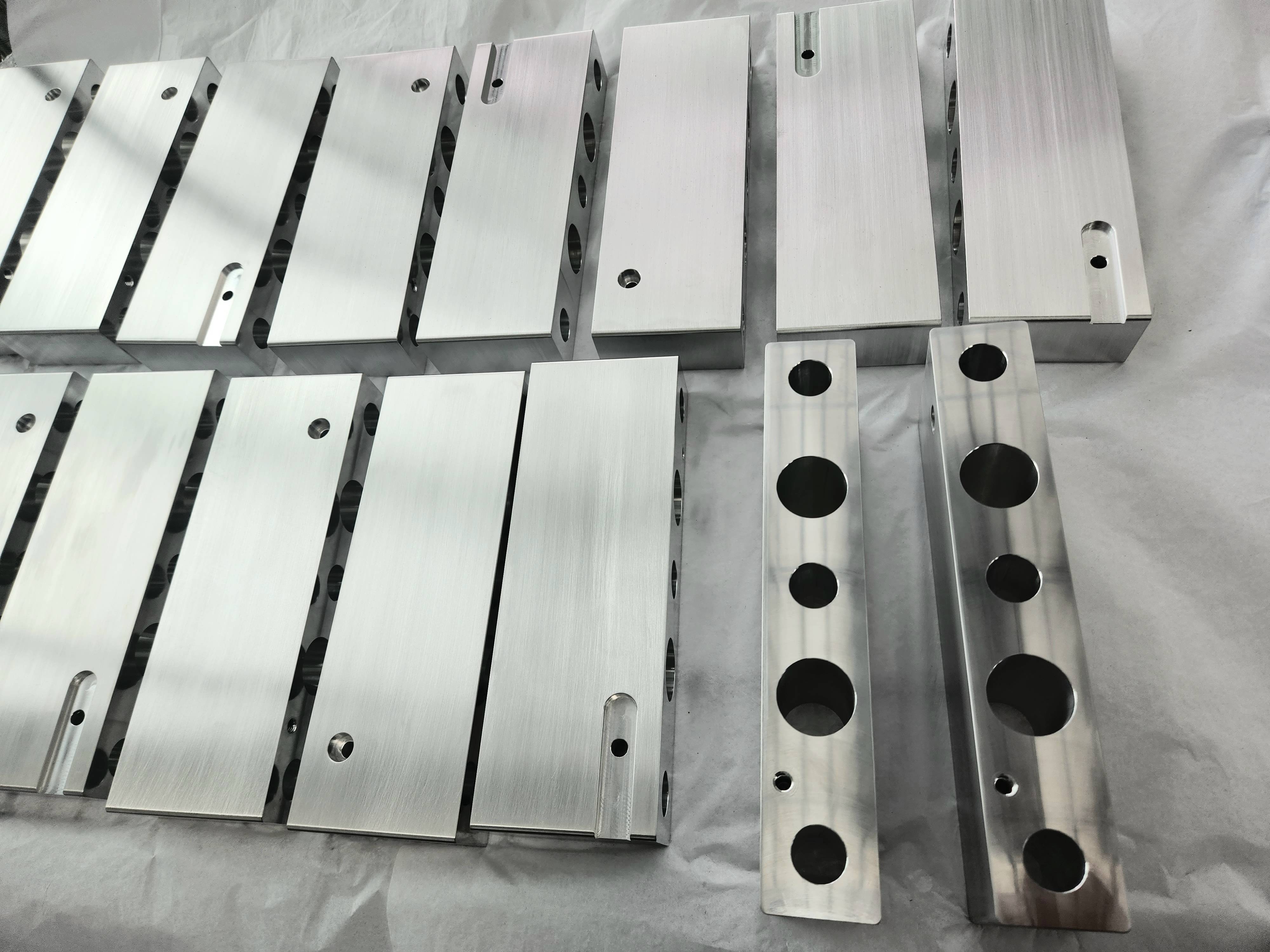

Mainly using lathes, milling machines, planers, drills, grinders, and other general machine tools to process mold parts and assemble various molds. Aluminum alloy parts mechanical processing can also be called CNC precision machining or automatic lathe machining, CNC lathe machining, etc.

Parts obtained by this method generally do not require further machining. Precision casting achieves higher shape and casting accuracy compared to traditional machining methods.

Powder metallurgy is a technology for manufacturing materials or products using metal powder as raw material, through mixing, forming, and sintering.

Solid powder is uniformly mixed with organic binders, then granulated, and injected into the mold cavity for curing and molding under a heated plasticized state using an injection molding machine.

The binder in the formed blank is removed by chemical or thermal decomposition, and the final product is obtained by sintering and densification.