PP (Polypropylene)

Polypropylene (PP) is a widely used thermoplastic polymer known for its versatility, durability, and cost-effectiveness.

Here's an introduction to PP material in CNC machining and mold applications:

Material Properties

Chemical Resistance:

PP exhibits excellent resistance to many chemicals, acids, and alkalis, making it suitable for various chemical and corrosive environments.

High Impact Strength:

It has good impact resistance, which allows PP parts to withstand moderate to heavy impacts without breaking or cracking.

Heat Resistance:

PP has a high melting point, typically around 160-170°C (320-338°F), making it suitable for applications requiring heat resistance.

Low Density:

PP is a lightweight material, which makes it ideal for applications where weight is a concern.

Good Electrical Insulation:

PP has excellent electrical insulation properties, making it suitable for electrical and electronic applications.

Recyclability:

PP is recyclable and can be reused in various applications, making it an environmentally friendly choice.

CNC Machining of PP

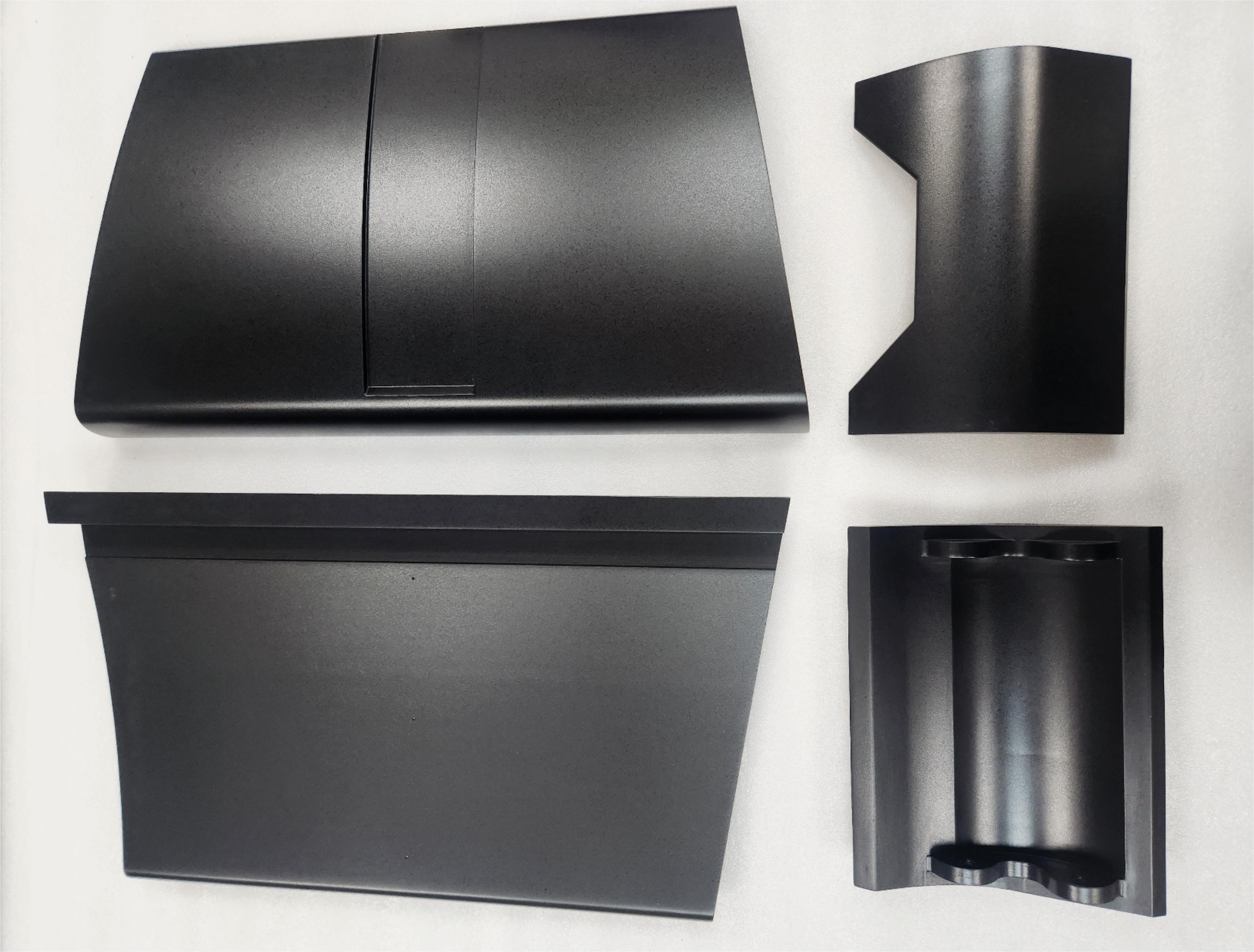

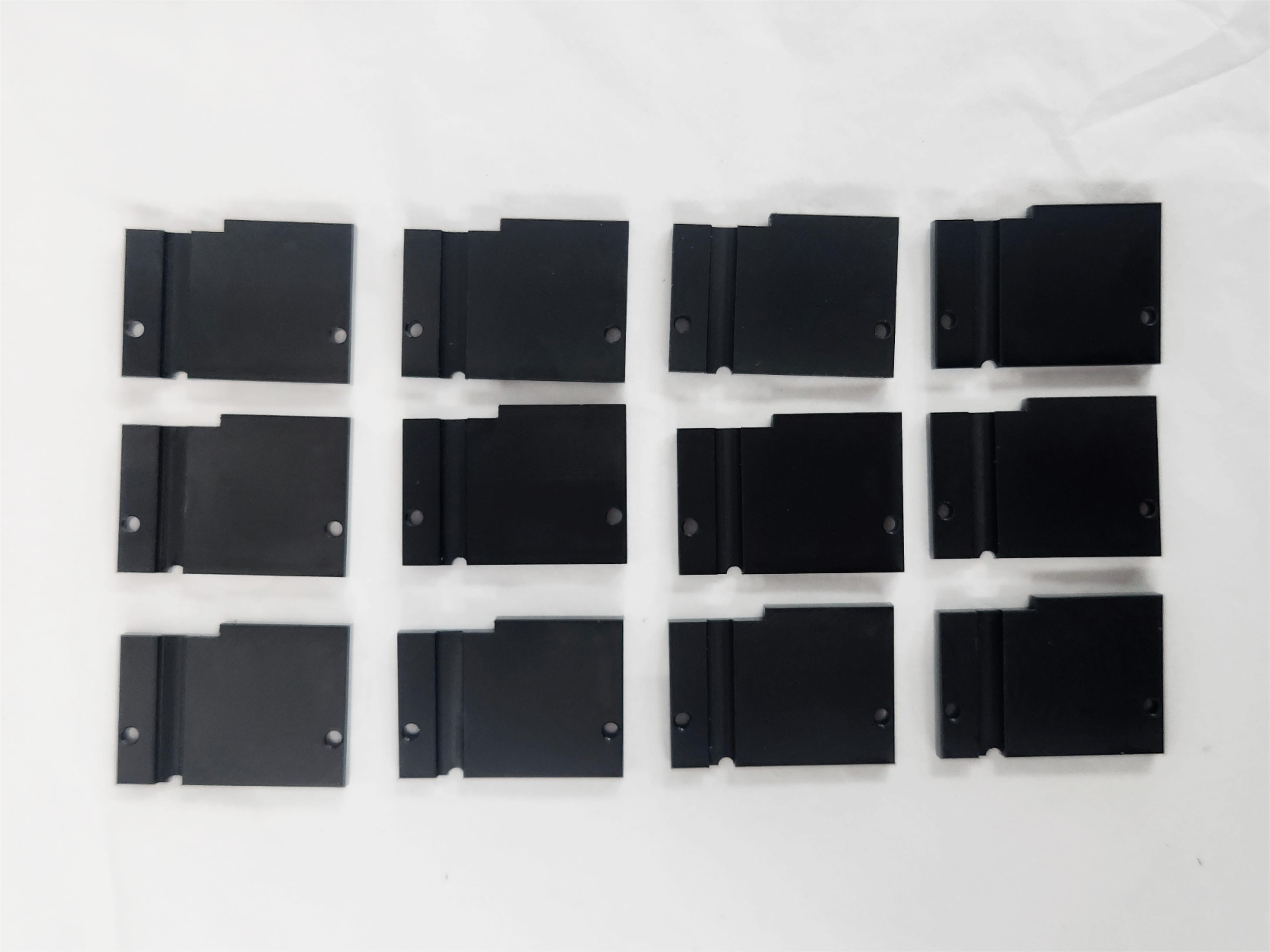

Milling:

PP can be milled into precise shapes and features using CNC milling machines. It offers good machinability and dimensional stability.

Turning:

CNC turning processes can be used to create cylindrical or curved PP parts with high precision.

Drilling and Tapping:

PP can be drilled and tapped to create holes and threads for assembly purposes.

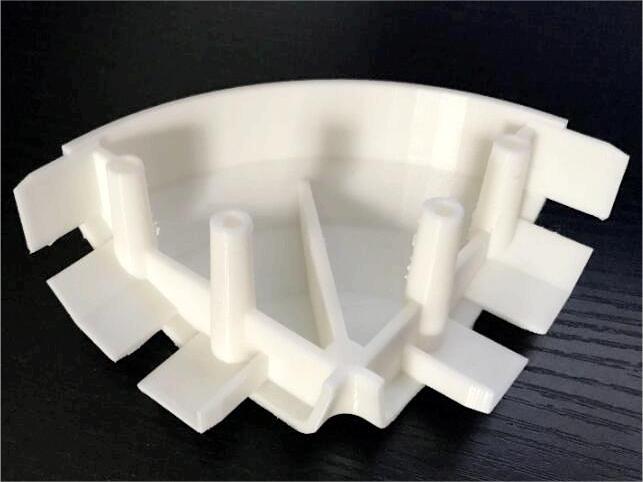

Mold Manufacturing with PP

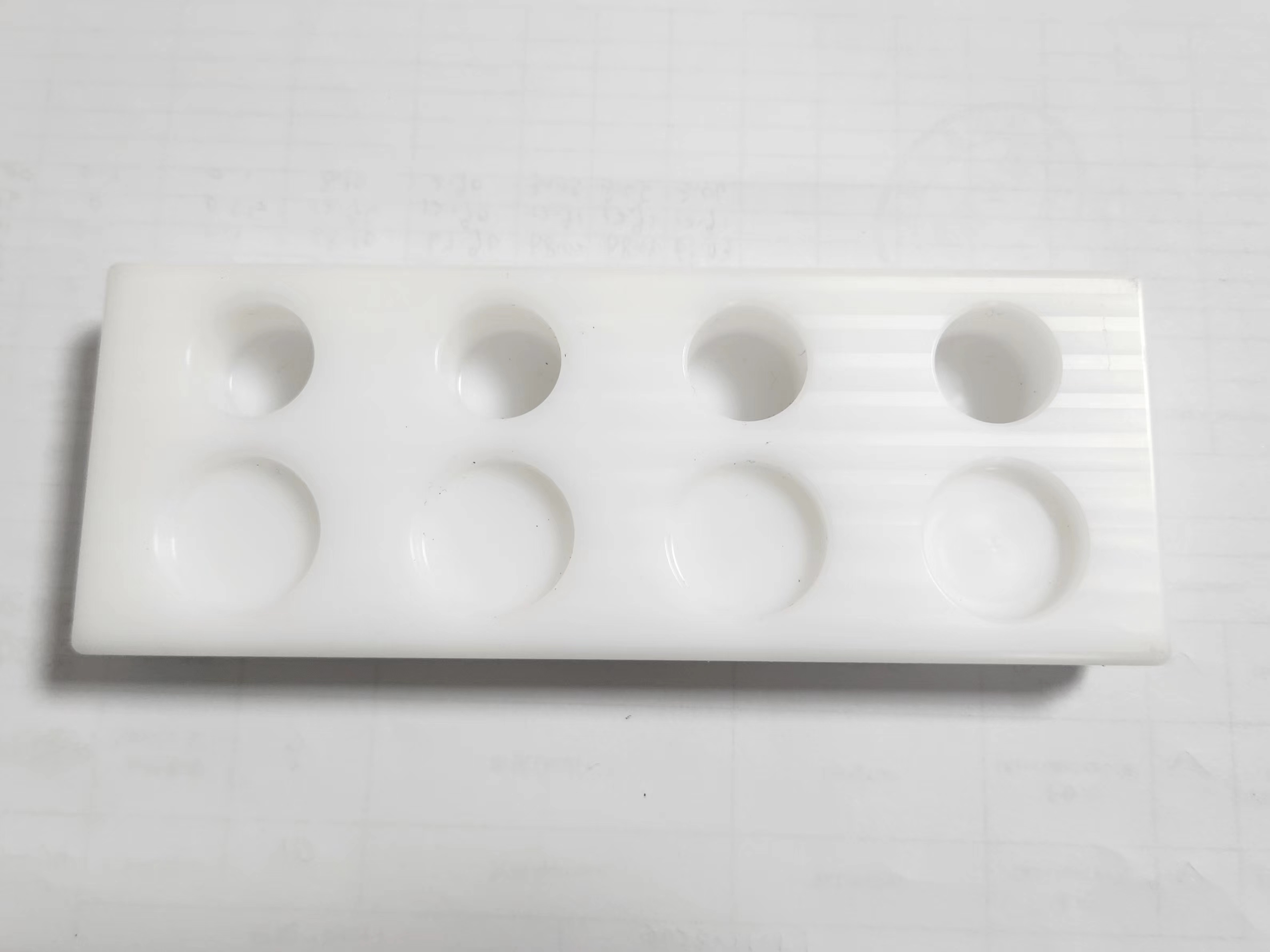

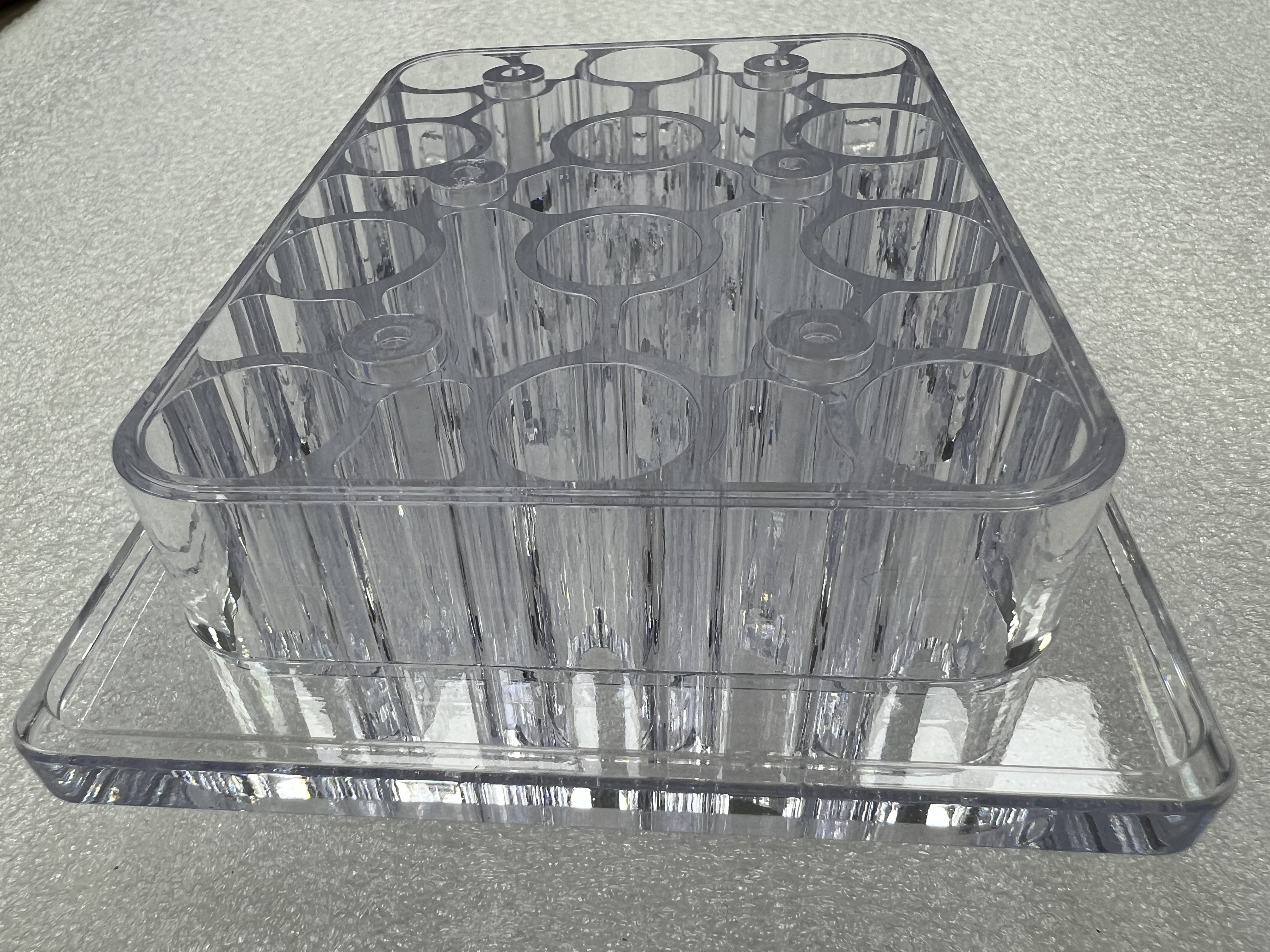

Prototype Molds:

PP is commonly used to create prototype molds due to its ease of machining and cost-effectiveness. It allows for rapid prototyping of plastic parts.

Injection Molds:

PP injection molds are used for mass production of plastic parts with high precision and repeatability.

PP's excellent flow properties make it suitable for injection molding processes.

Applications

- **Packaging:** PP is widely used in packaging applications such as bottles, containers, caps, and closures due to its durability, chemical resistance, and lightweight nature.

- **Automotive:** PP is used in automotive interiors for components such as dashboards, door panels, and trim parts due to its impact resistance and low cost.

- **Medical Devices:** PP is used in medical devices and equipment such as syringes, containers, and tubing due to its sterilizability and chemical resistance.

- **Consumer Goods:** PP is used in various consumer goods such as toys, kitchenware, and household appliances due to its durability and ease of molding.

- **Industrial Components:** PP is used for industrial components such as piping systems, tanks, and fittings due to its chemical resistance and durability.

In summary, PP is a versatile material suitable for CNC machining and mold manufacturing, offering excellent chemical resistance, impact strength, and heat resistance.

Its properties make it ideal for a wide range of applications across industries.