SLS Prototyping

Selective Laser Sintering (SLS) is an additive manufacturing technique that utilizes a high-powered laser to selectively fuse powdered materials, typically polymers or metals, layer by layer, based on a 3D digital model.

SLS 3D printers use high-powered lasers to melt small particles of polymer powder.

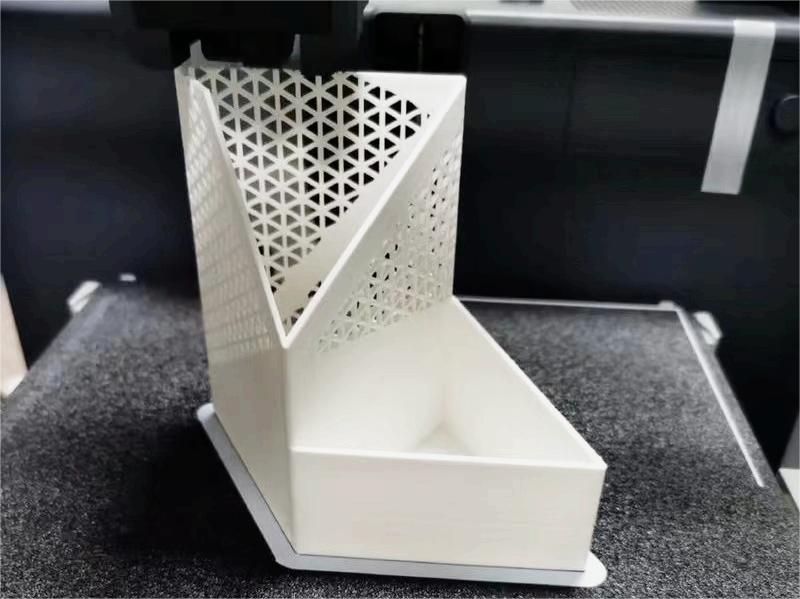

The unmelted powder supports the object during the printing process, eliminating the need for specialized supporting structure.

This makes SLS suitable for complex geometries, including internal features, cut edges, thin walls, and negative features.

SLS prints produce parts with excellent mechanical properties and strength similar to injection molded parts.

SLS supports a wide range of materials, including various polymers, composites, and metals, each tailored to specific applications and performance requirements.

The most commonly used material for selective laser sintering is nylon, a popular thermoplastic engineering plastic with excellent mechanical properties. Nylon is lightweight and strong,

Nylon is lightweight, strong, flexible and stable against impact, chemicals, heat, UV light, water and dirt.