Electroplishing

Electroplishing, also known as electropolishing, is an electrochemical process used primarily to polish, passivate, and deburr metal surfaces.

It involves the immersion of the metal object to be treated in an electrolyte bath and applying an electric current to the object and a counter electrode (usually made of an inert material like stainless steel).

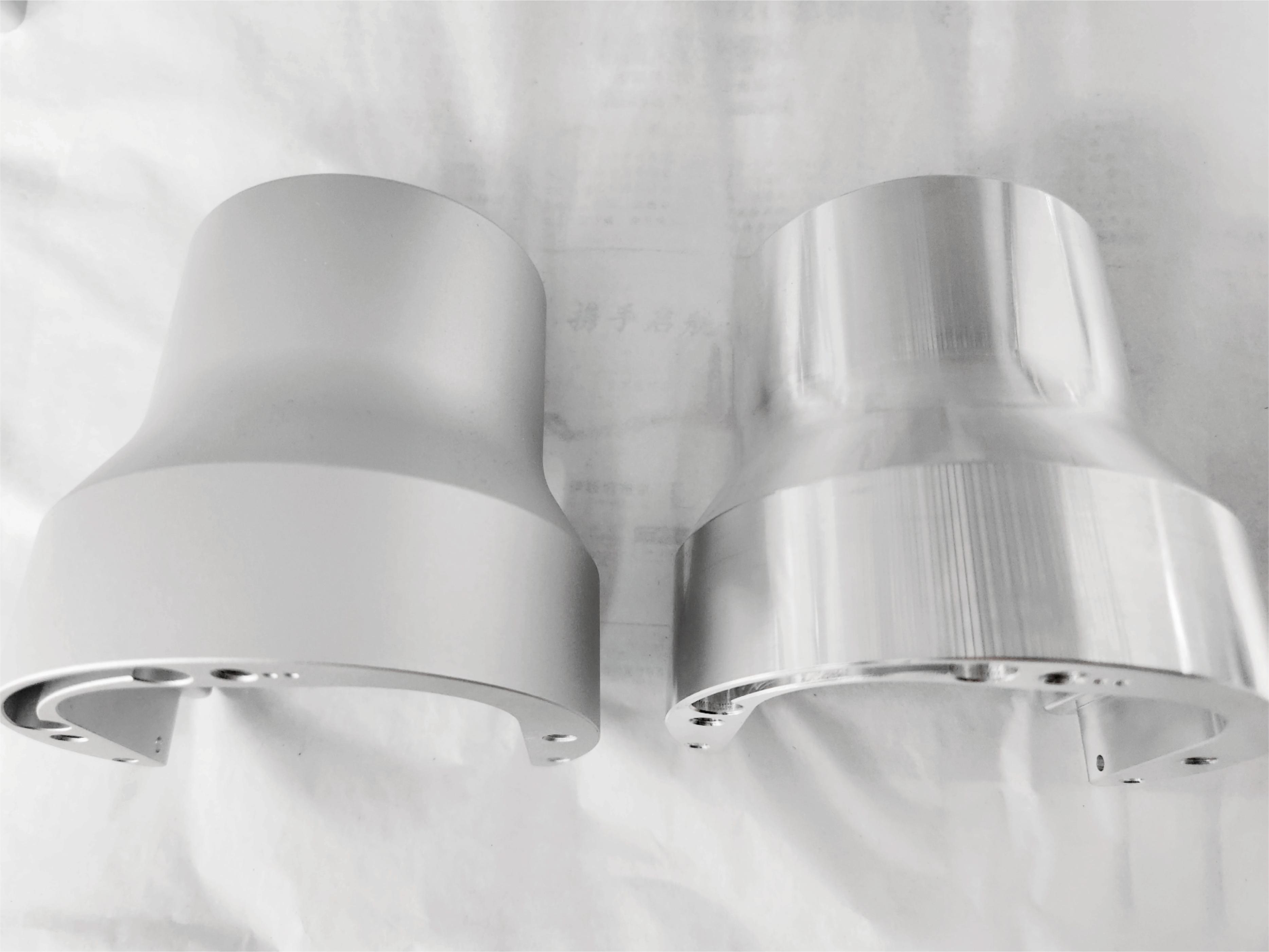

During the process, metal ions are removed from the surface of the object, resulting in the leveling of microscopic peaks and valleys, which leads to a smoother and more reflective surface finish.

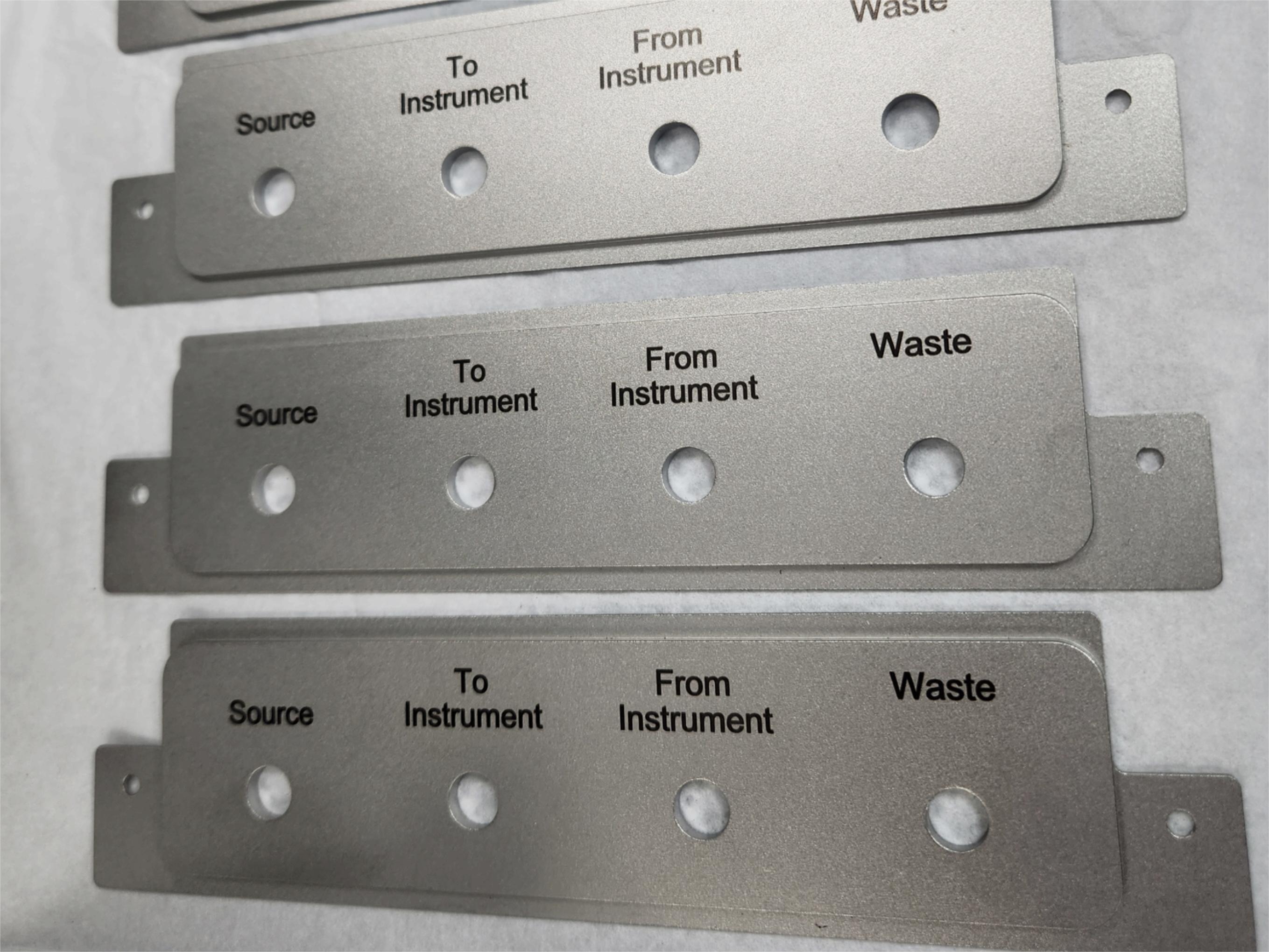

Additionally, electroplishing can also help in removing embedded contaminants and oxides from the surface of the metal, thereby improving its corrosion resistance.

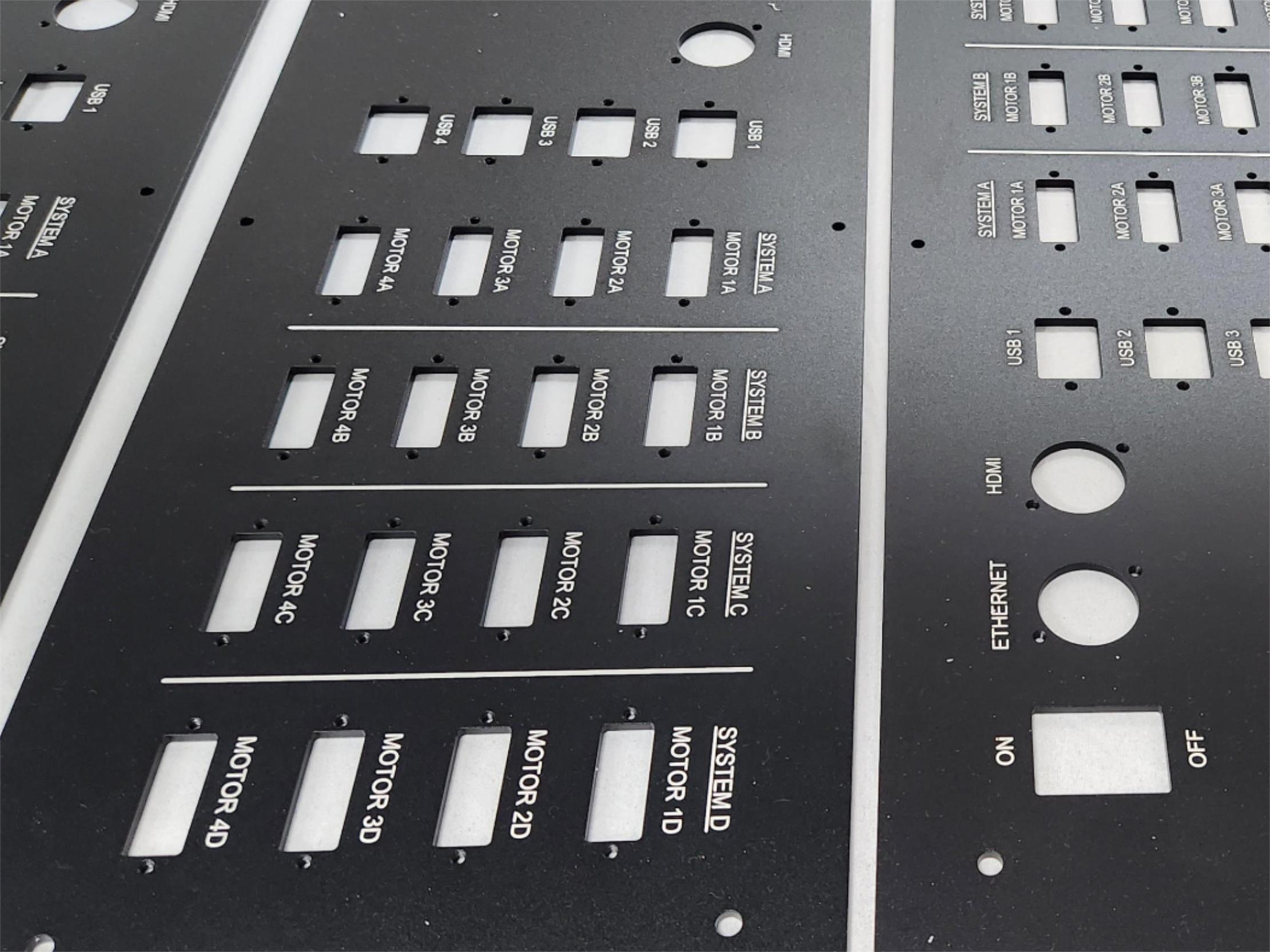

This process finds applications in various industries such as aerospace, medical devices, automotive, electronics, and jewelry manufacturing, where high-quality surface finishes are desired for both aesthetic and functional purposes.