Brass CNC

Unveiling Brass CNC Machining:

CNC (Computer Numerical Control) machining has long been hailed as a game-changer in the manufacturing industry.

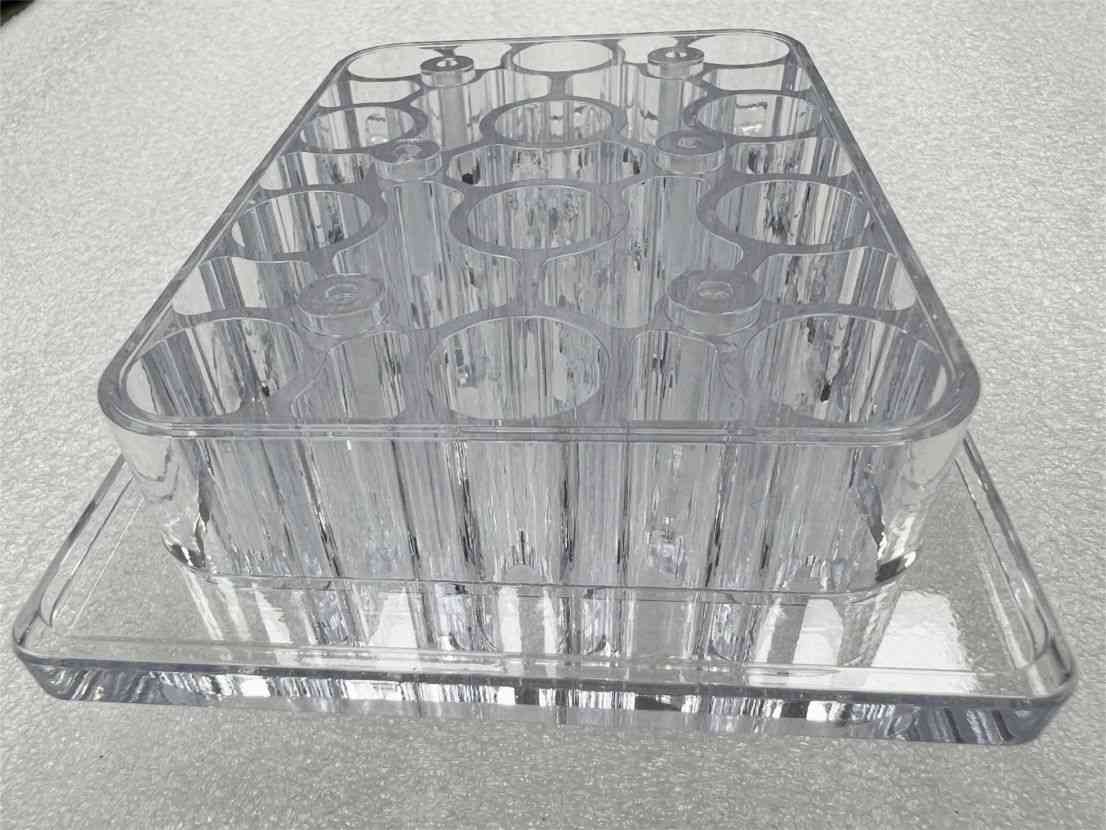

Brass, known for its durability and aesthetic appeal, finds a perfect match in CNC machining, offering manufacturers a versatile solution for crafting high-quality components.

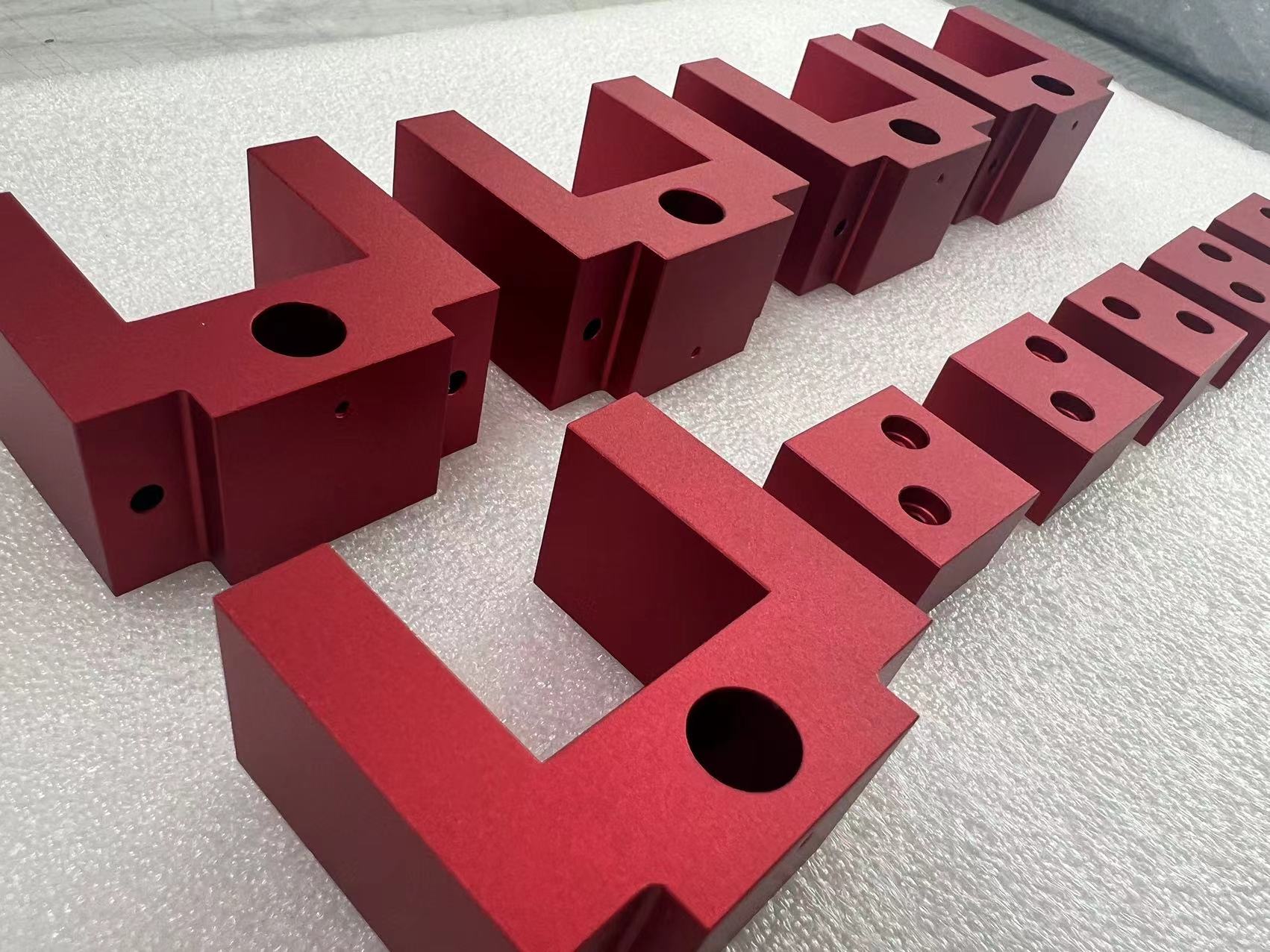

1. Precision Engineering:

Brass CNC machining enables the production of intricate parts with micron-level precision.

From complex geometries to fine surface finishes, this technology ensures that each component meets exact specifications, elevating the quality standards of the final product.

2. Material Versatility:

Brass's unique properties make it an ideal candidate for a wide range of applications, from decorative fixtures to functional components.

With CNC machining, manufacturers can leverage the material's malleability and corrosion resistance to create bespoke solutions tailored to diverse industries.

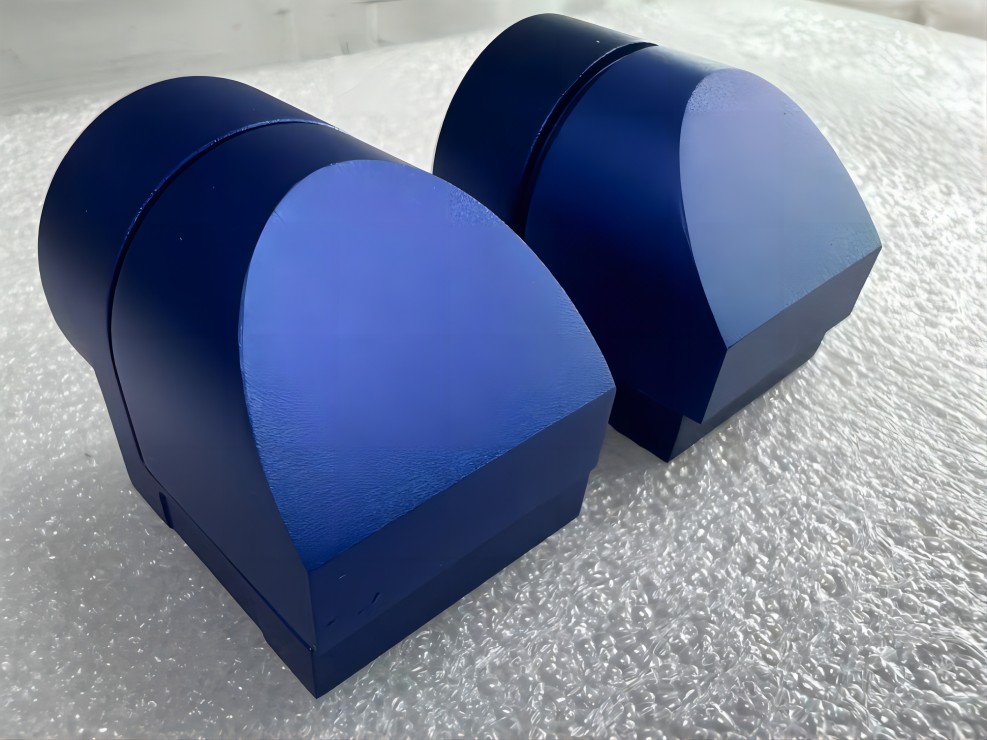

3. Cost-Efficiency:

While brass is often associated with luxury, CNC machining offers a cost-effective means of production, especially for low-volume manufacturing.

By minimizing material wastage and optimizing machining processes, businesses can achieve economies of scale without compromising on quality.