Aluminum Alloy Prototypes

Aluminum alloys have long been favored in various industries for their exceptional strength-to-weight ratio, corrosion resistance, and machinability.

However, their role in medical device prototyping has gained significant traction in recent years due to several key advantages:

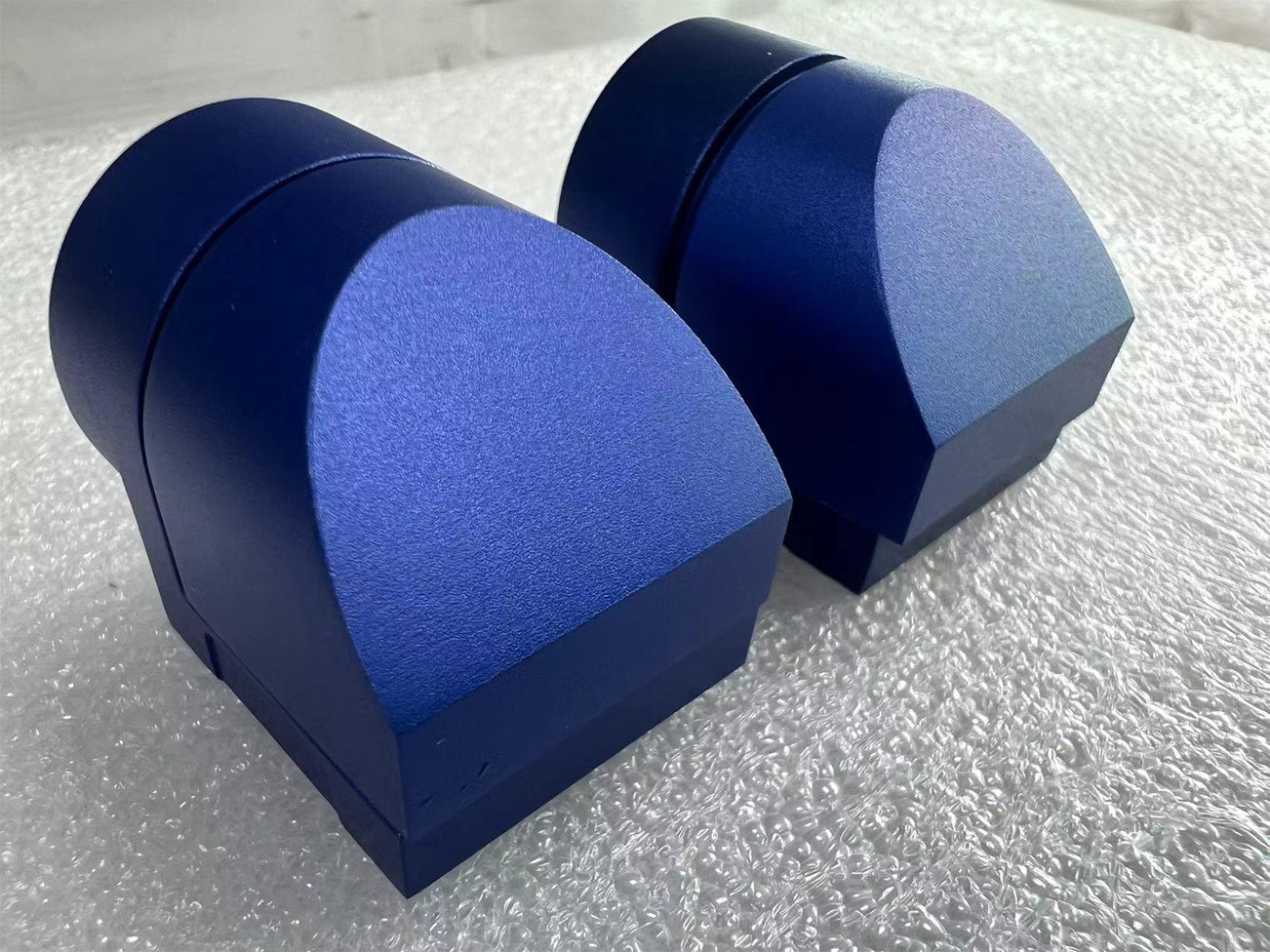

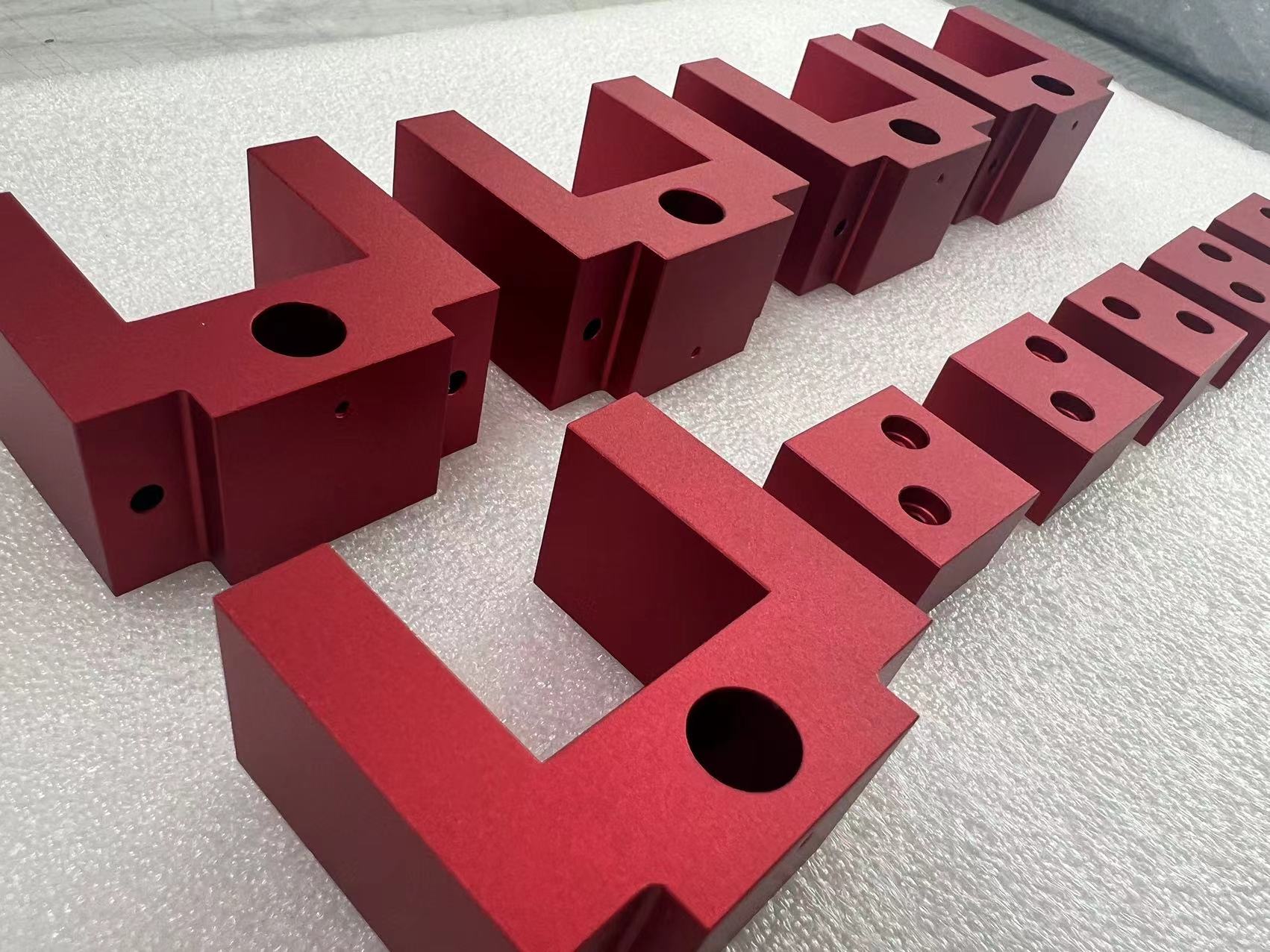

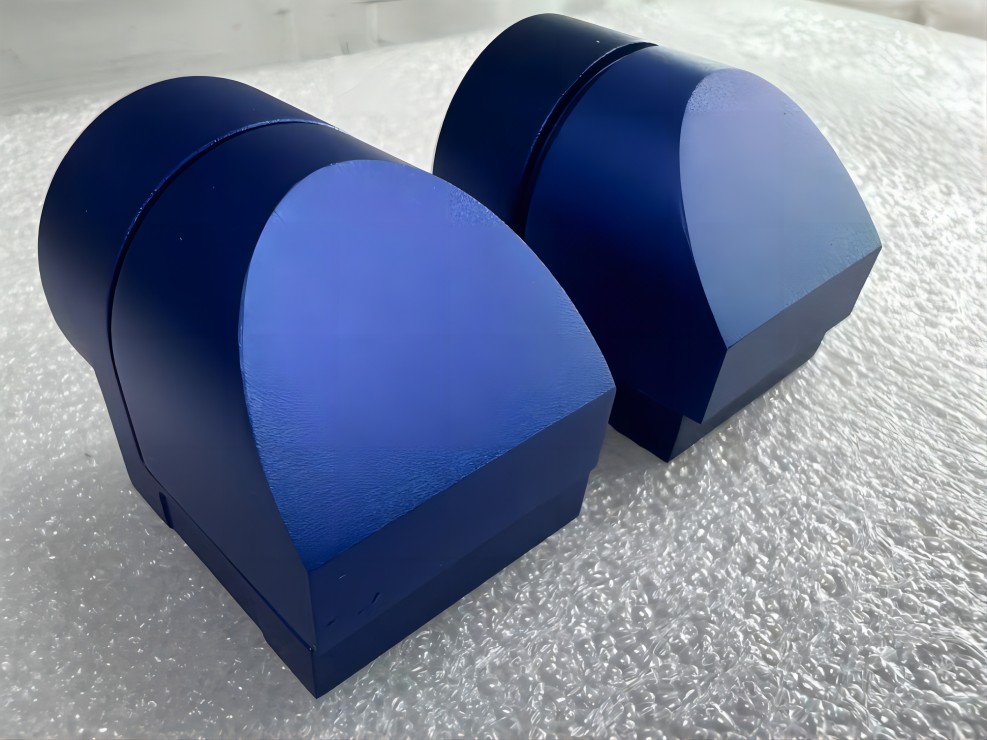

Precision Engineering:

Aluminum alloys offer remarkable precision, making them ideal for intricate medical device components.

With advanced machining techniques, manufacturers can achieve tight tolerances and complex geometries crucial for the functionality of medical devices.

Cost-Efficiency:

Compared to traditional materials like stainless steel or titanium, aluminum alloys are more cost-effective.

This cost efficiency is particularly beneficial in the prototyping phase, where multiple iterations may be necessary to refine designs and optimize performance.

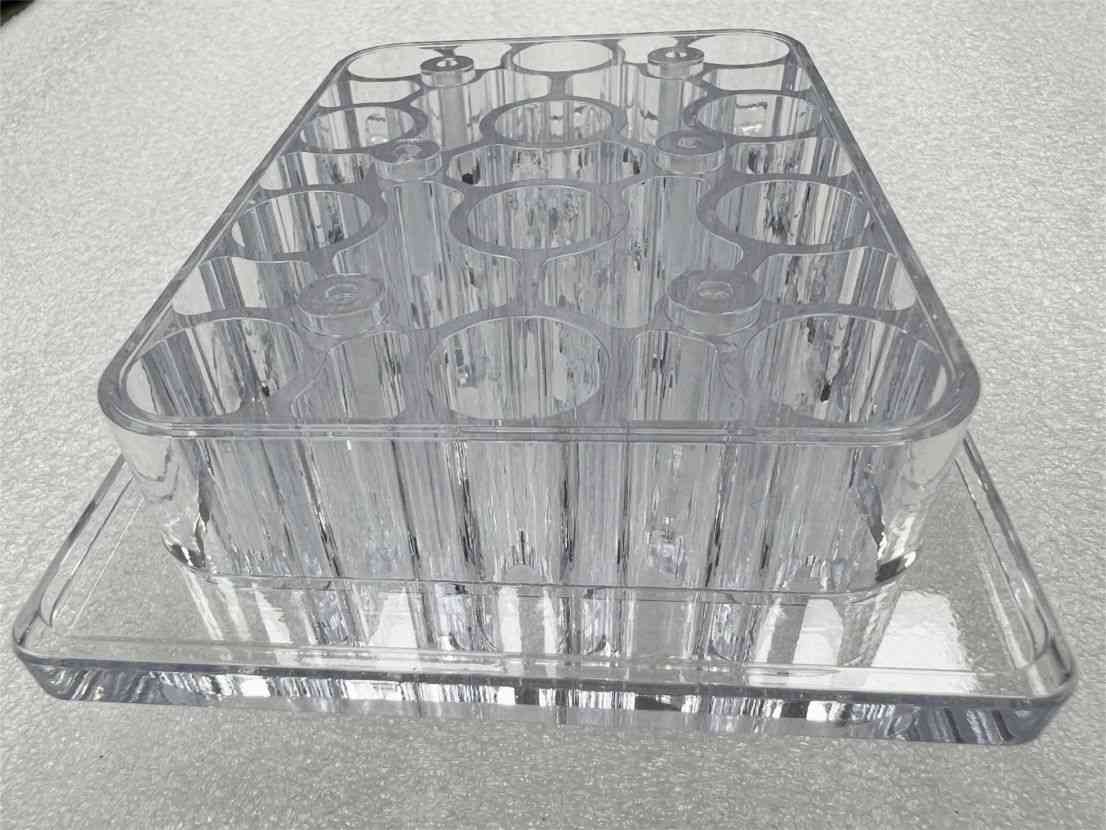

Rapid Prototyping: Accelerating Innovation in Medical Device Development

Rapid prototyping technologies have revolutionized the way medical devices are conceptualized, designed, and validated.

Advanced manufacturing processes such as 3D printing, CNC machining, and additive manufacturing, rapid prototyping.