ABS 3D Printing

Commonly used SLA materials

SLA materials are liquid resins.

Industrial systems have a wider choice of materials than desktop and SLA printers, which allows for better control of the mechanical properties of the model.

SLA materials (thermosets) are more fragile than FDM or SLS (thermoplastic) materials, so SLA models typically cannot be used to withstand large loads.

Of course future advances in materials may change this.

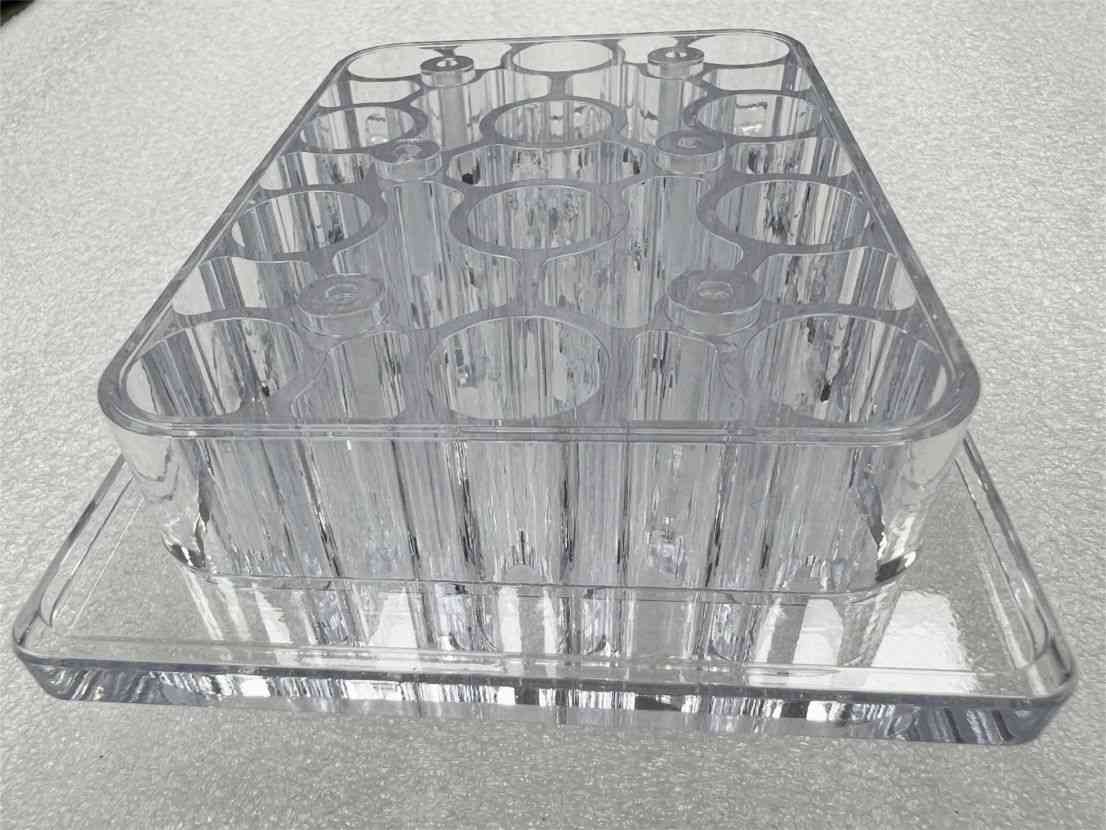

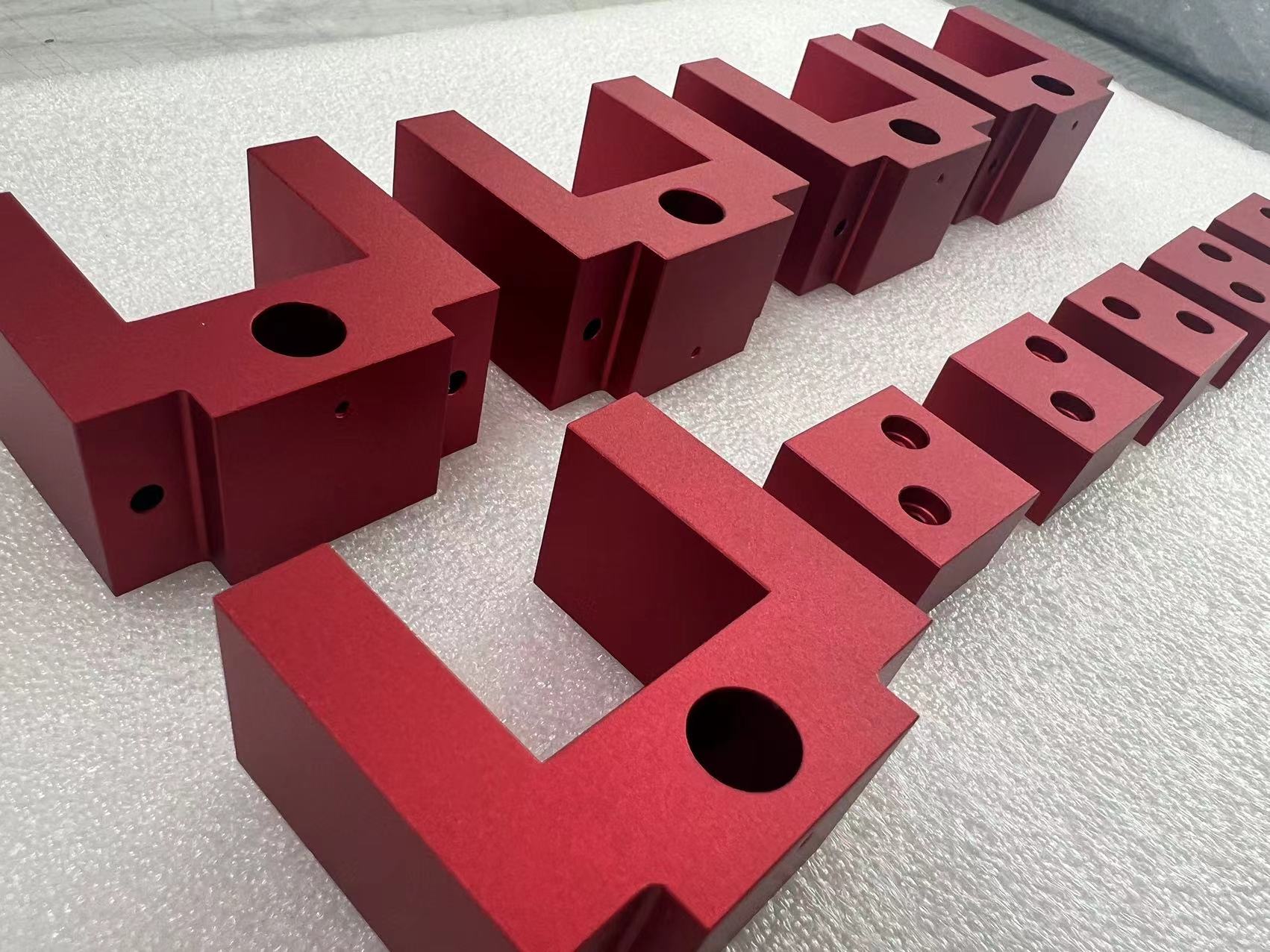

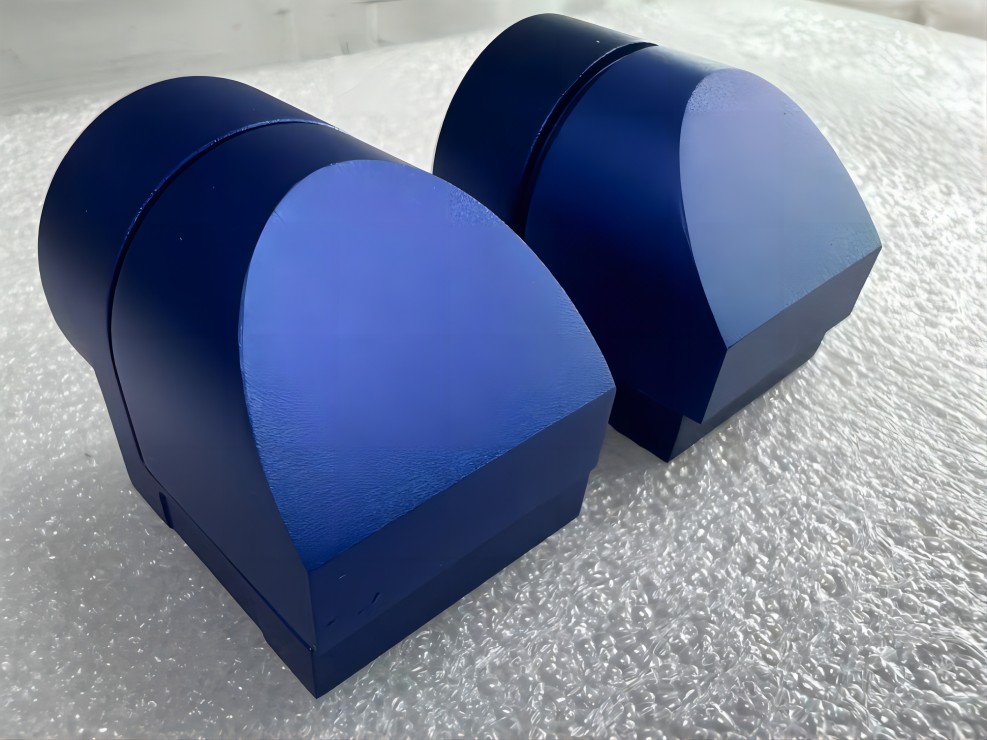

SLA can produce highly complex structures, and the superior surface quality makes it the first choice for visual prototyping and modeling, ensuring a polished and professional appearance.

SLA is particularly beneficial for projects such as interference fit visualization in complex assemblies or simulated lenses for lighting fixtures.SLA rapid prototype parts are ideal for both functional testing and aesthetic presentation.

Briefly explain the whole process from inquiry to order fulfillment:

1. Mutual understanding:

We need to understand your products, needs, quantity, etc..

You understand our team, site, equipment, with qualifications, etc..

2. Sign a confidentiality agreement and send drawings for quotation:

According to the specific situation, provide manual detailed quotation.

3. Order creation, production, inspection, payment, shipment.

4. Provide after-sales service, responsible for your product from start to finish.

Prototype verification stage, small batch production, large batch production for the market.