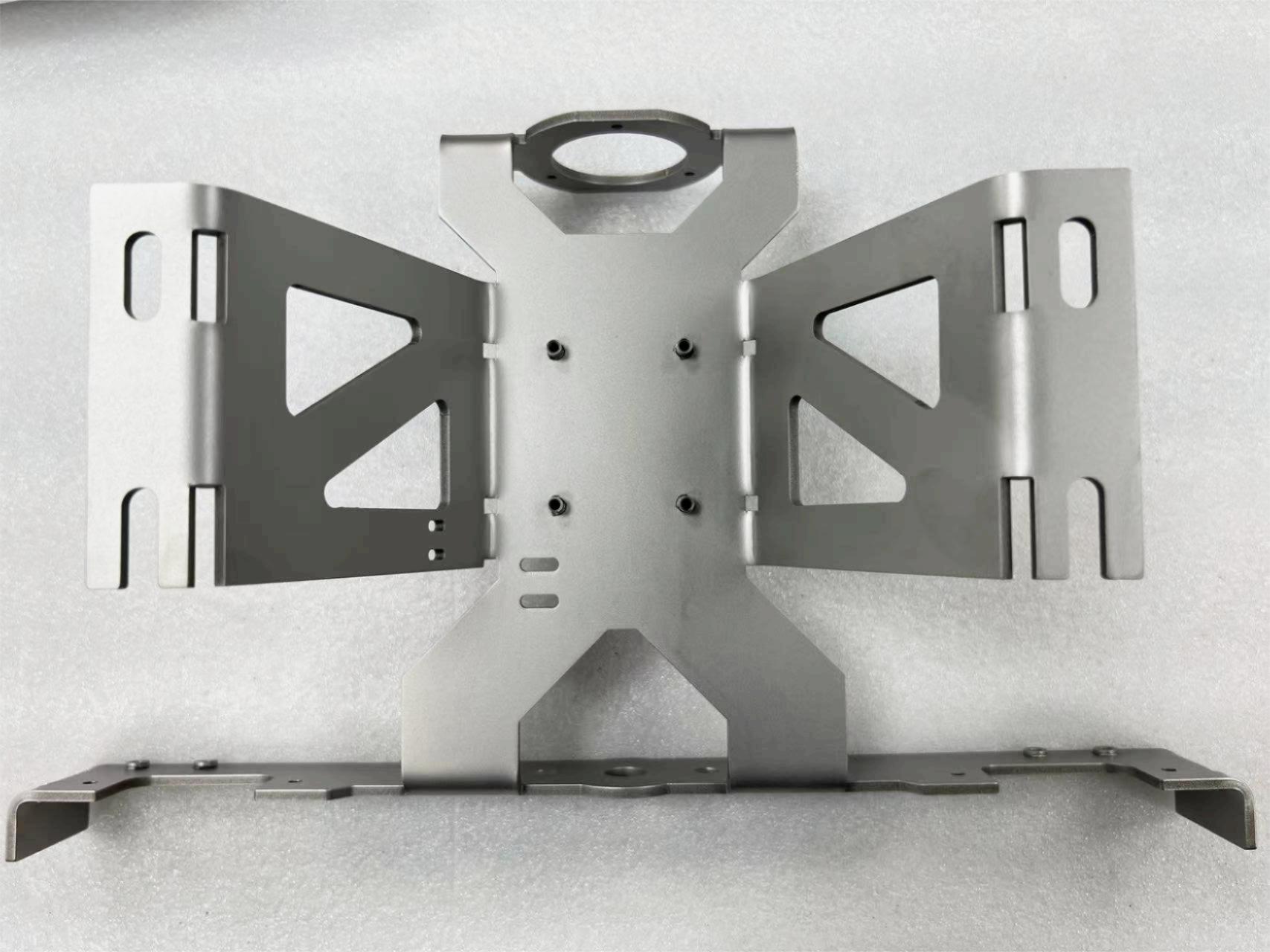

Sheet metal fabrication

Sheet metal parts, what are they?

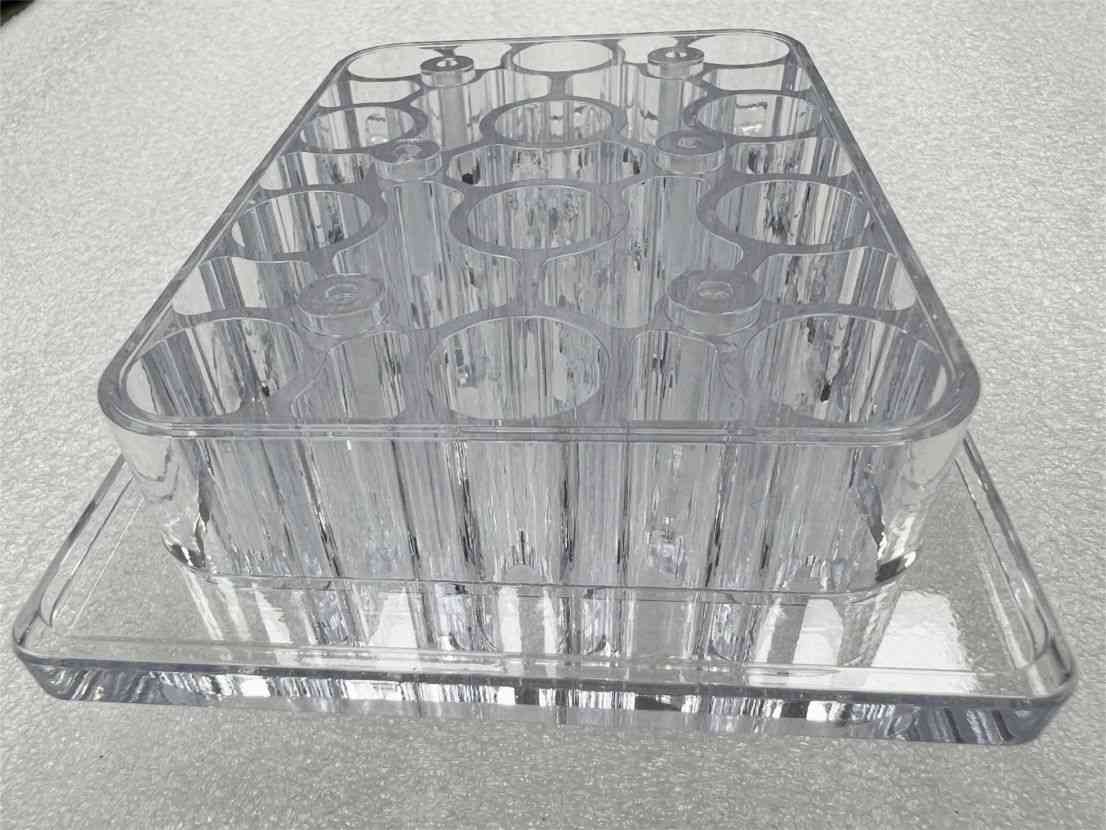

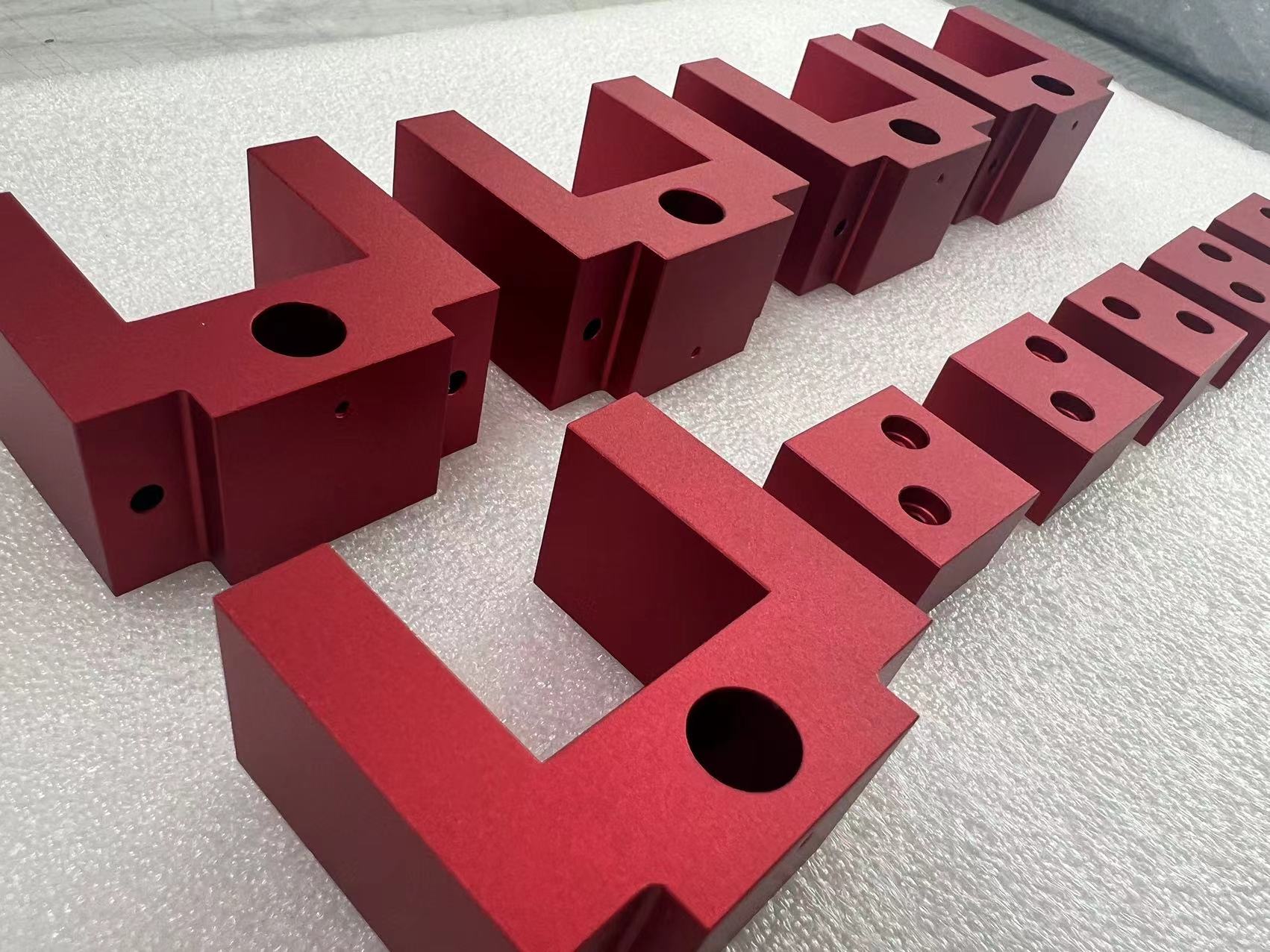

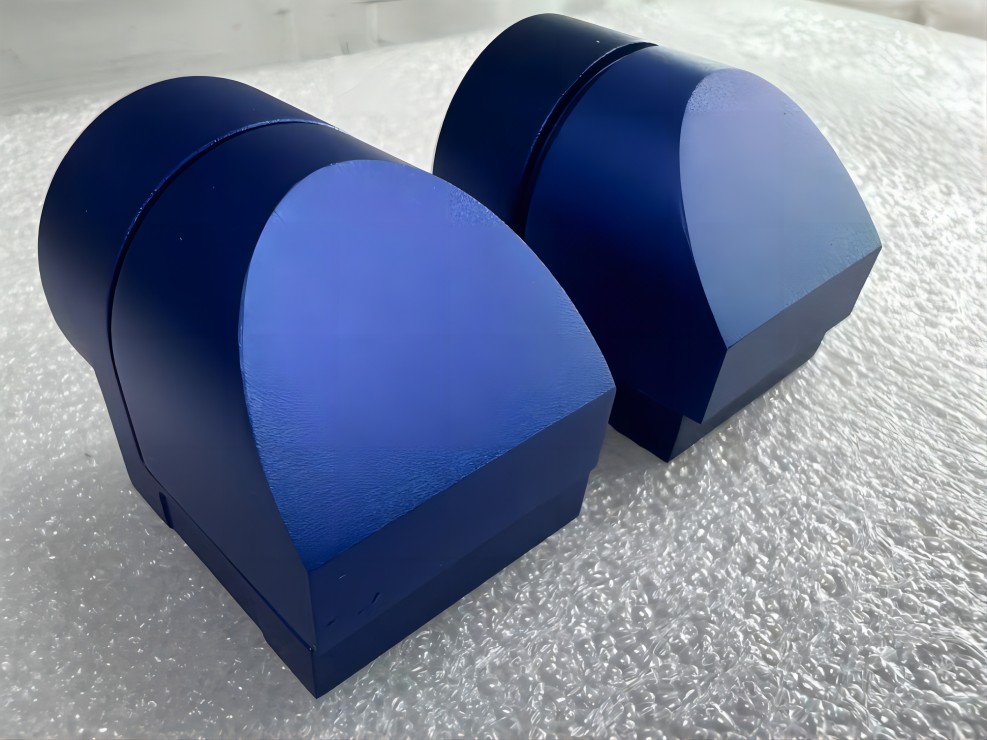

Sheet metal parts are a comprehensive cold processing technology for metal thin plates (usually less than 6mm), including shearing, punching/cutting/compounding, folding, welding, riveting, splicing, forming, and other processes to produce components.

Features:

Uniform Thickness: For a part, the thickness of all parts is consistent.

Lightweight, High Strength, Conductive, Low Cost, Good Performance in Large-Scale Mass Production.

Since sheet metal parts are formed by a piece of metal thin plate through bending, the contact of the bending edges is not sealed and there is no rigid connection.

If not handled, it will affect the strength. The usual treatment method is welding.

The technical requirements on the drawing include: welding angle, welding angle, rounding.

Common uses of sheet materials in daily life include computer case cabinets, television back panels, automobile shells, air conditioning casings, integrated terminal housings, charging station enclosures, and so on.

In the process of sheet metal fabrication, the entire process of gradually altering the shape, size, material properties of parts, or the welding of components until the manufacturing of sheet metal parts that meet the shape and size requirements is referred to as sheet metal processing.

For relatively complex structural components, the production process generally involves many steps such as material preparation, unfolding and layout, cutting of blanks, forming, and assembly.

Additionally, cold sheet metal processing is often combined with welding, metal cutting, heat treatment, and inspection processes to form a complete product manufacturing process.