Common Materials and Applications for Precision Components

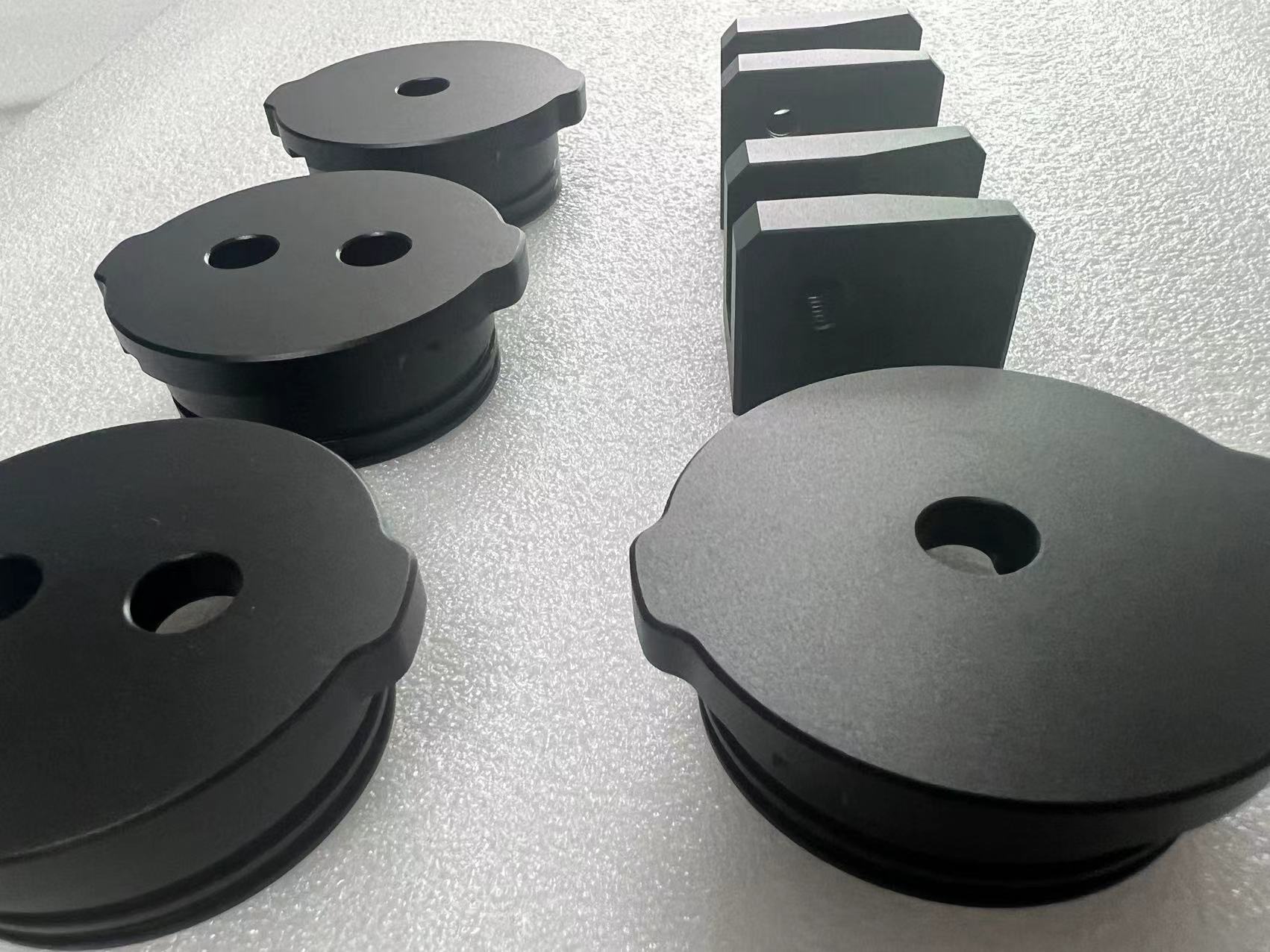

The Importance of Precision Component Fabrication

Precision components are crucial parts of various equipment, instruments, and systems, and the quality of their fabrication directly affects the performance, lifespan, and safety of the entire product.

With the continuous improvement of our country's technological innovation capabilities, precision component fabrication has become an integral part of social industrial development.

Therefore, selecting materials suitable for precision component fabrication is crucial.

1. Metal Materials:

Metal materials are the most widely used materials in precision component fabrication, featuring good mechanical and processing properties.

Common metal materials include steel, aluminum, copper, etc., suitable for various fields such as machinery, electronics, aerospace, etc.

2. Ceramic Materials:

Ceramic materials possess advantages such as high hardness, wear resistance, and high-temperature resistance, making them suitable for manufacturing wear-resistant and high-temperature-resistant precision components.

Examples include alumina, silicon carbide, etc., widely used in ceramic engines, precision bearings, and other fields.

3. Plastic Materials:

Plastic materials are lightweight, easy to process, and low-cost, suitable for manufacturing structurally simple and low-demand precision components.

Examples include polyimide, polycarbonate, etc., widely used in electronics, automotive, and other fields.

4. Composite Materials:

Composite materials combine two or more materials to leverage their respective advantages, forming a new type of material.

Composite materials offer advantages such as high strength, high toughness, and low density, suitable for manufacturing high-performance precision components.

Examples include carbon fiber composite materials, glass fiber composite materials, etc., widely used in aerospace, automotive manufacturing, and other fields.

Selecting materials suitable for precision component fabrication requires thorough consideration of component performance requirements, processing techniques, and operating environments.

With the continuous development of technology, we look forward to the emergence of new materials and technologies, providing more possibilities for precision component fabrication.

The Exquisite Craftsmanship of

The Exquisite Craftsmanship of

Our 3D Printing: A Brief Intr

Our 3D Printing: A Brief Intr

Ruiyi's Control of Mold Qualit

Ruiyi's Control of Mold Qualit

Reliable Mold Manufacturer | E

Reliable Mold Manufacturer | E