Our 3D Printing: A Brief Introduction

①Personalized Customization

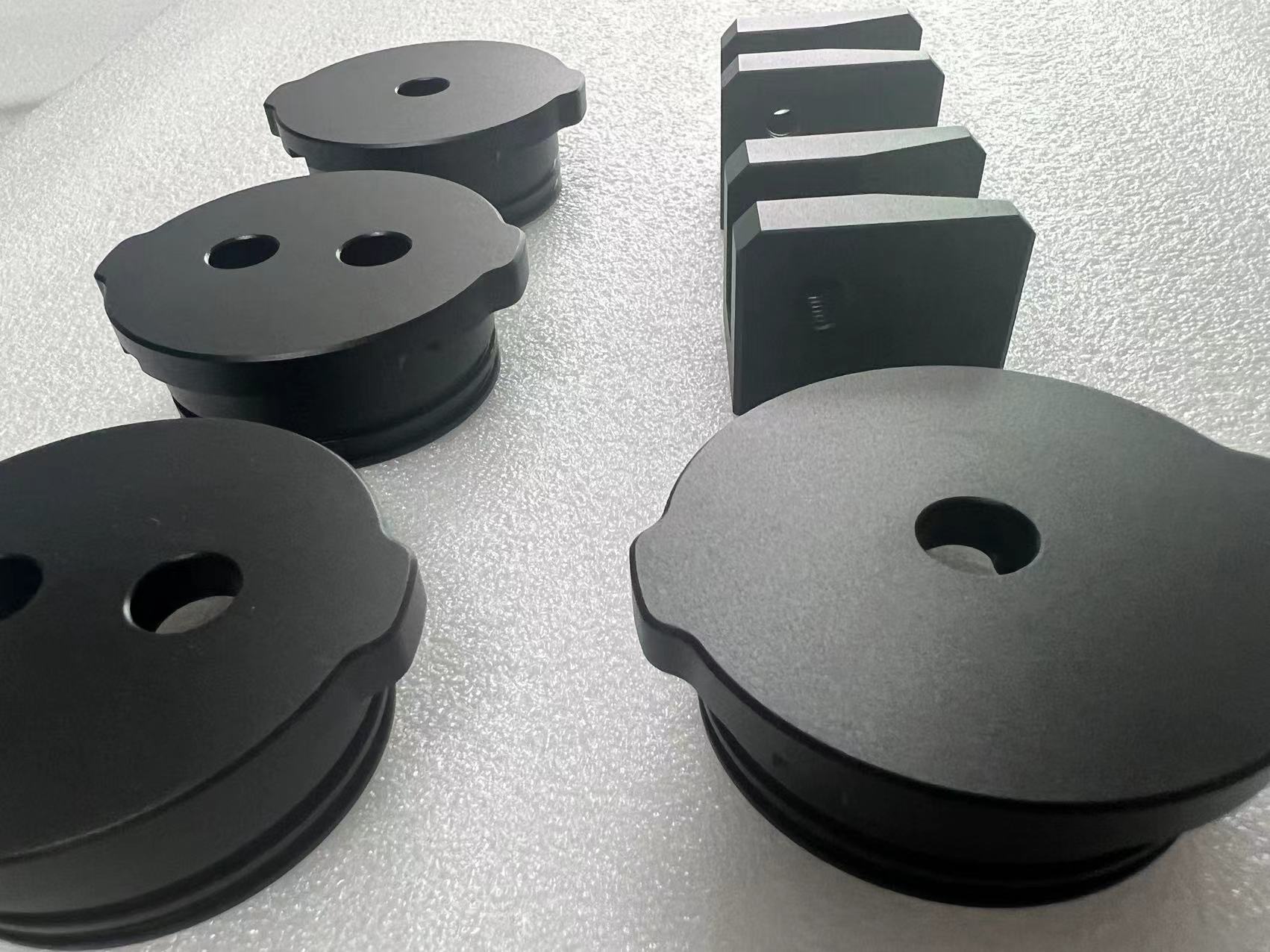

One of the greatest advantages of 3D printing technology is its ability to achieve personalized customization.

In traditional manufacturing methods, producers often resort to large-scale, standardized production to reduce costs.

However, this approach fails to meet the diverse and personalized demands of consumers.

In contrast, 3D printing technology can easily achieve personalized customization.

With the help of 3D printing technology, designers can create one-to-one designs tailored to the needs of each consumer.

This customized production method not only enhances the usability of products but also satisfies consumers' pursuit of personalization.

For example, in the medical field, 3D printing technology can customize the most suitable implants according to the specific conditions of patients, thereby improving treatment effectiveness.

②Efficient Production

3D printing technology manufactures objects by layering, which results in higher production efficiency compared to traditional manufacturing methods.

Reduced Processing Steps:

In traditional manufacturing processes, multiple steps such as casting, forging, and welding are often required. These steps are not only time-consuming but also prone to waste. However, 3D printing technology can directly produce finished products from digital models, greatly simplifying the production process.

Material Savings:

By layering materials only where necessary, 3D printing technology can save a significant amount of raw materials compared to traditional manufacturing methods.

Shorter Cycle:

The production cycle of 3D printing technology is short, with designs to manufacturing potentially completed in just a few hours. This is crucial for product development and iteration.

③Cost Reduction

3D printing technology offers significant advantages in cost reduction.

Reduced Material Waste:

As mentioned earlier, 3D printing technology adds material only where needed, greatly reducing material waste.

Elimination of Mould Costs:

In traditional manufacturing processes, the production of molds is often required. However, 3D printing technology can directly manufacture products based on digital models, eliminating the need for molds.

Design Optimization:

3D printing technology allows for the design of complex structures, thereby reducing the number of parts and lowering costs.

Reduced Inventory Pressure:

3D printing technology enables on-demand production, eliminating the need for companies to stockpile large amounts of inventory, thus reducing inventory costs.

The Exquisite Craftsmanship of

The Exquisite Craftsmanship of

Our 3D Printing: A Brief Intr

Our 3D Printing: A Brief Intr

Ruiyi's Control of Mold Qualit

Ruiyi's Control of Mold Qualit

Reliable Mold Manufacturer | E

Reliable Mold Manufacturer | E