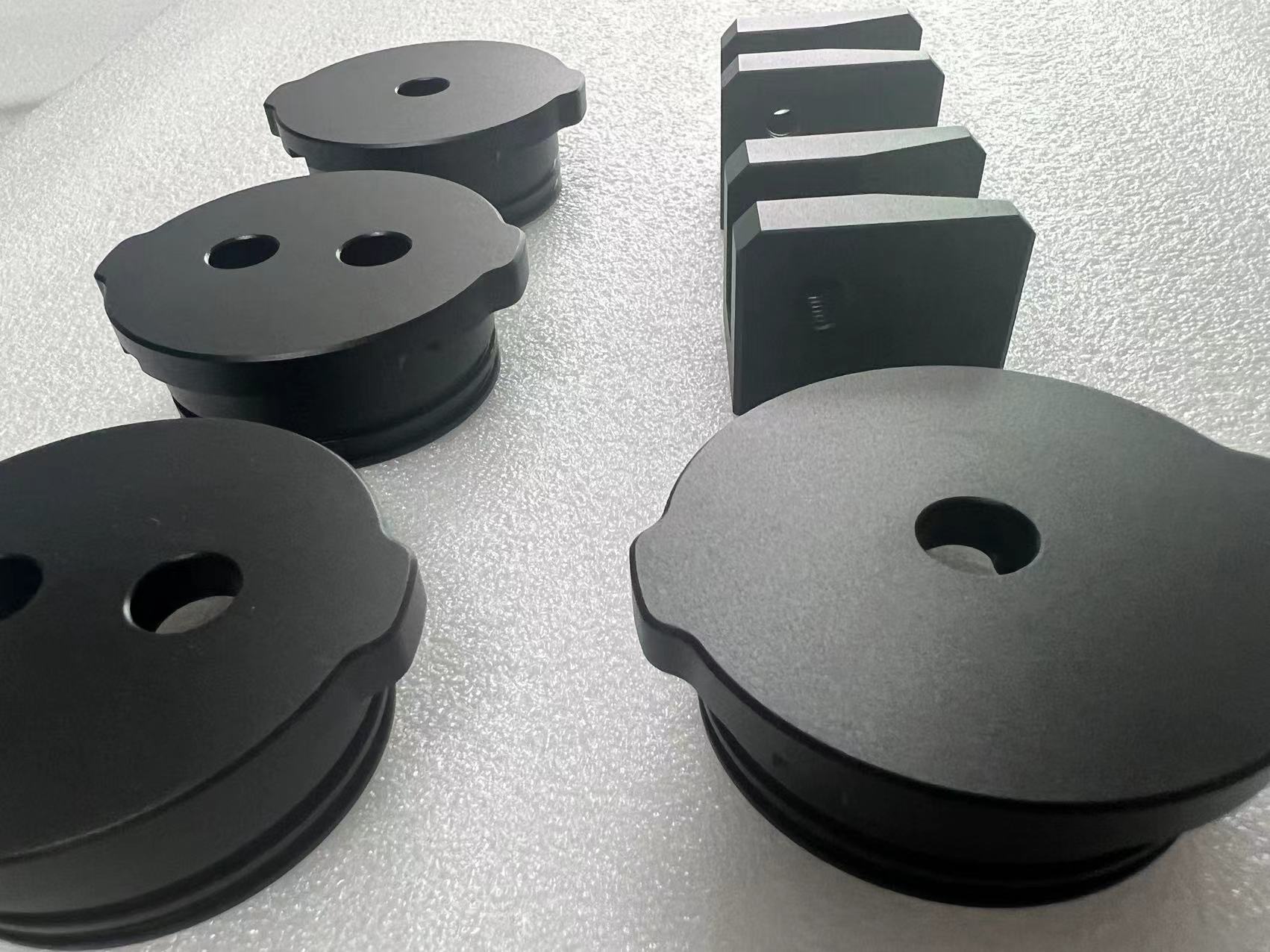

Ruiyi's Control of Mold Quality

As a direct manufacturer of molds, we deeply understand that quality control of molds is paramount for a mold manufacturing company to be reliable.

It's also the most concerning issue for our customers.

As experienced manufacturers in this field for many years, we always adhere to the principle of high efficiency and high quality to serve our customers.

1. Quality Control from the Beginning

From receiving the customer's requirements, we carefully review the customer's drawings and documents, fully understand the customer's needs without omission, including product dimensional accuracy, shape, surface treatment, materials, and quality.

This ensures that producing high-quality molds later will help improve production efficiency, reduce defect rates, and lower production costs. Long lifespan, good wear resistance, and sustainability are beneficial to the enterprise.

2. Key Aspects of Quality Control

Design Stage

Mold design is the first step in mold quality control.

At the design stage, we fully consider factors such as product functionality, structure, materials, and manufacturing processes to ensure that the mold design is reasonable, compact, easy to process, and maintain.

Additionally, we use advanced CAD/CAE/CAM technology to improve the accuracy and reliability of mold design.

Material Selection

The choice of mold material has a significant impact on mold quality.

Mold materials should have high hardness, strength, toughness, wear resistance, and corrosion resistance.

When selecting mold materials, we fully consider factors such as product environment, production processes, and costs to ensure reasonable material selection.

Processing Technology

Mold processing technology is a critical aspect of mold quality control.

Reasonable processing technology can improve the manufacturing quality and efficiency of molds.

Mold processing mainly includes CNC machining, electrical discharge machining, and heat treatment.

During the processing, we strictly control process parameters to ensure dimensional accuracy, shape, and surface quality of the molds.

Assembly and Debugging

Mold assembly and debugging are important steps to ensure mold quality.

During the assembly process, we ensure the precision of the fit of each mold component, avoiding looseness, wear, and other phenomena.

During the debugging process, we adjust the guiding, positioning, clamping, and other systems of the mold to ensure stable operation during production.

Quality Inspection

Mold quality inspection is an important means of mold quality control.

We use advanced inspection equipment and technology to test parameters such as mold dimensions, shape, surface quality, and hardness to ensure that mold quality meets design requirements.

After-Sales Service

Mold quality control also includes after-sales service.

We promptly understand customer feedback, carry out maintenance, modifications, and optimizations of the molds, to improve mold lifespan and customer satisfaction.

From receiving customer requirements to material selection, processing, quality inspection, and after-sales service, in order to manufacture better products and gain customer trust, each of our procedures is well-organized.

Try us, and we believe you won't be disappointed.

The Exquisite Craftsmanship of

The Exquisite Craftsmanship of

Our 3D Printing: A Brief Intr

Our 3D Printing: A Brief Intr

Ruiyi's Control of Mold Qualit

Ruiyi's Control of Mold Qualit

Reliable Mold Manufacturer | E

Reliable Mold Manufacturer | E