The Exquisite Craftsmanship of Aluminum Machining, China Factory

1. Casting Technology

Casting is the first step in aluminum processing, directly affecting the quality of aluminum parts.

Reliable aluminum processors utilize advanced casting techniques such as sand casting and metal casting to ensure dense structure and stable performance of aluminum parts.

2. Rolling and Extrusion Technology

Rolling and extrusion are common methods for aluminum processing.

By adjusting the parameters of rolling and extrusion processes, aluminum parts of different shapes and sizes can be achieved.

Reliable aluminum processors master advanced rolling and extrusion techniques, enabling the production of high-performance aluminum parts.

3. Forging Technology

Forging is a method of processing aluminum by applying pressure to deform it. Forged aluminum parts possess high strength, good toughness, and ductility.

Reliable aluminum processors employ advanced forging techniques such as hot forging and warm forging to enhance aluminum part performance.

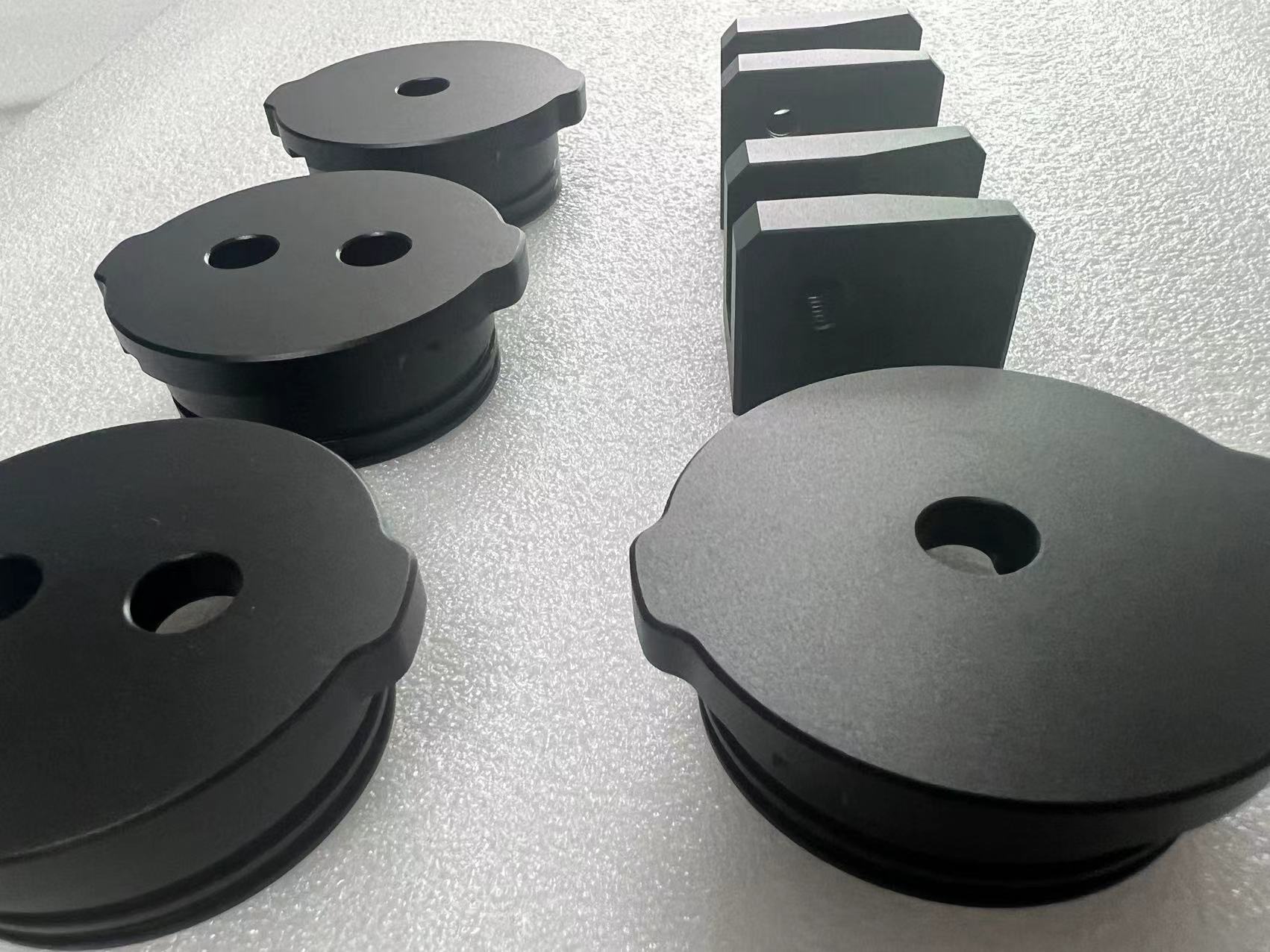

4. Machining Technology

Machining is the final step in aluminum processing, directly affecting the dimensional accuracy and surface quality of aluminum parts.

Reliable aluminum processors have high-precision machining equipment and techniques, such as CNC lathes, milling machines, and grinders, to ensure that aluminum parts meet design requirements.

The Exquisite Craftsmanship of

The Exquisite Craftsmanship of

Our 3D Printing: A Brief Intr

Our 3D Printing: A Brief Intr

Ruiyi's Control of Mold Qualit

Ruiyi's Control of Mold Qualit

Reliable Mold Manufacturer | E

Reliable Mold Manufacturer | E