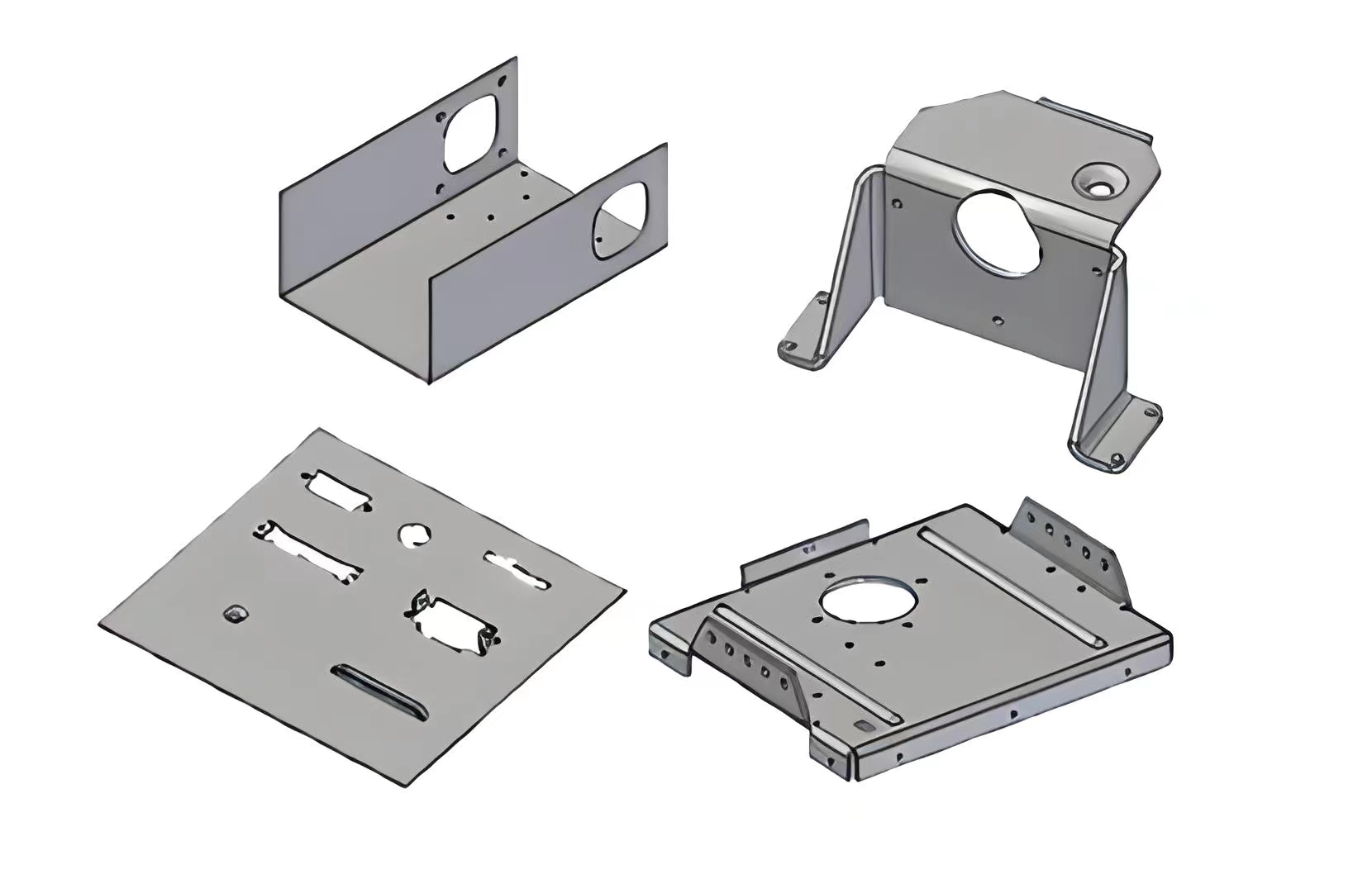

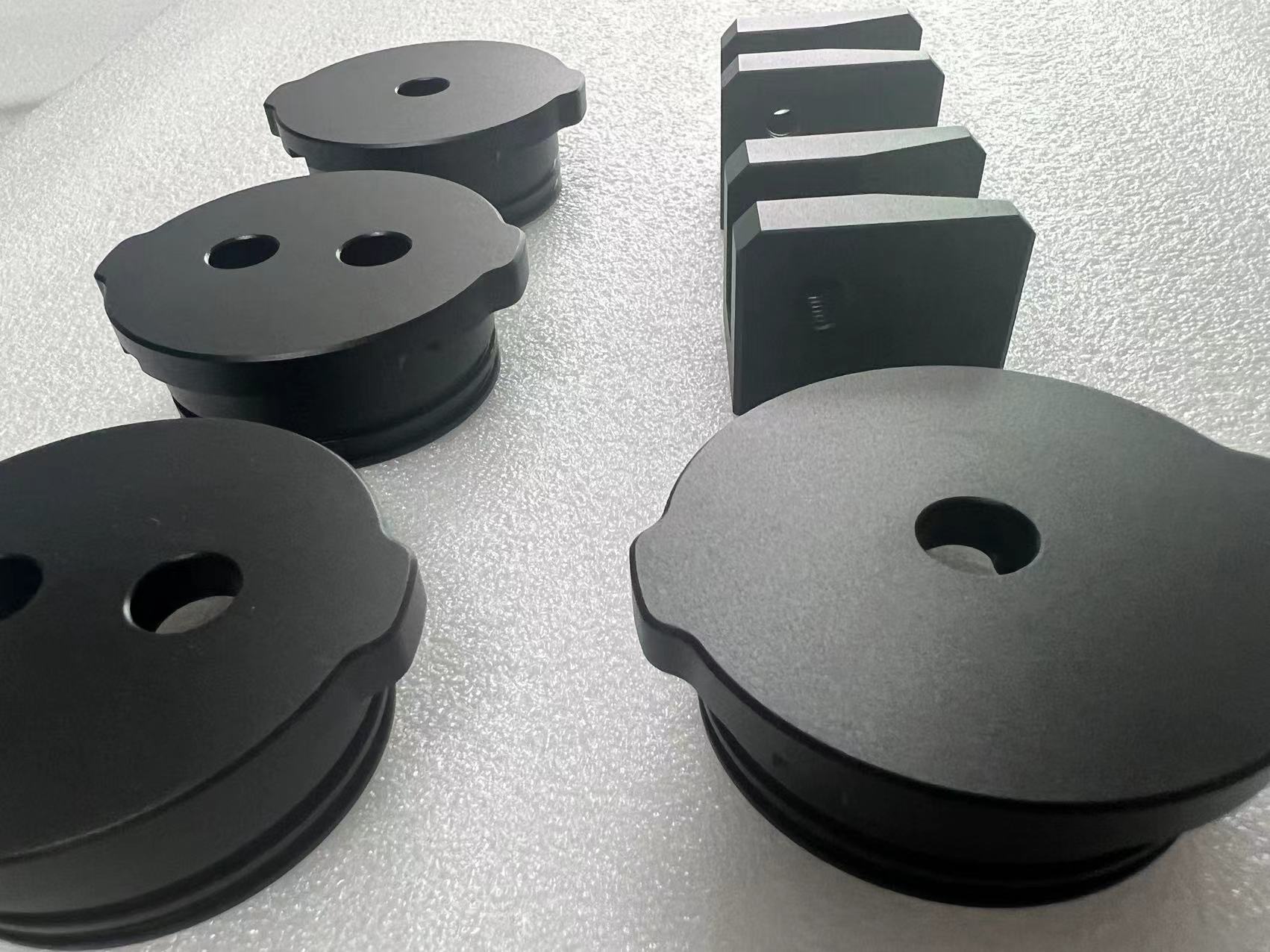

Sheet metal fabrication and processing

The application of sheet metal and other mechanical processing materials is extensive.

They are not only widely used in various forms within the mechanical industry but also have gained broad application spaces in sectors such as automotive manufacturing, aerospace, and aviation.

Moreover, they are rapidly expanding and popularizing in other industries and fields.

The functionality of sheet metal materials is determined by factors such as their mechanical processing methods, appearance, and material properties.

They can reflect the mechanical maturity of the production process and the advancement of manufacturing technology.

With the rapid development of China's machinery manufacturing industry and the increasingly complex processing and manufacturing requirements of sheet metal parts,

a series of processing and treatment processes such as unfolding calculation, bending, welding, and spraying of corresponding metal materials are directly related to the final output quality, appearance, and stability of sheet metal parts.

To maintain good appearance, sufficient strength, and necessary precision, it is crucial to calculate the dimensions of sheet metal parts during the processing.

Sheet metal bending is one of the more significant processes in the manufacturing process.

The effectiveness of bending will directly affect the dimensions and appearance characteristics of the final product, thereby influencing the subsequent selection of welding processes and the difficulty of operation.

In our next blog post, we go into detail about sheet metal bending.

How to choose sheet metal fabrication for the many choices of factories?

For this you need to directly consider the factory that can produce samples for prototypes, is it possible to make samples for free? At RuiYi, of course there is! We welcome your inquiries.

The Exquisite Craftsmanship of

The Exquisite Craftsmanship of

Our 3D Printing: A Brief Intr

Our 3D Printing: A Brief Intr

Ruiyi's Control of Mold Qualit

Ruiyi's Control of Mold Qualit

Reliable Mold Manufacturer | E

Reliable Mold Manufacturer | E