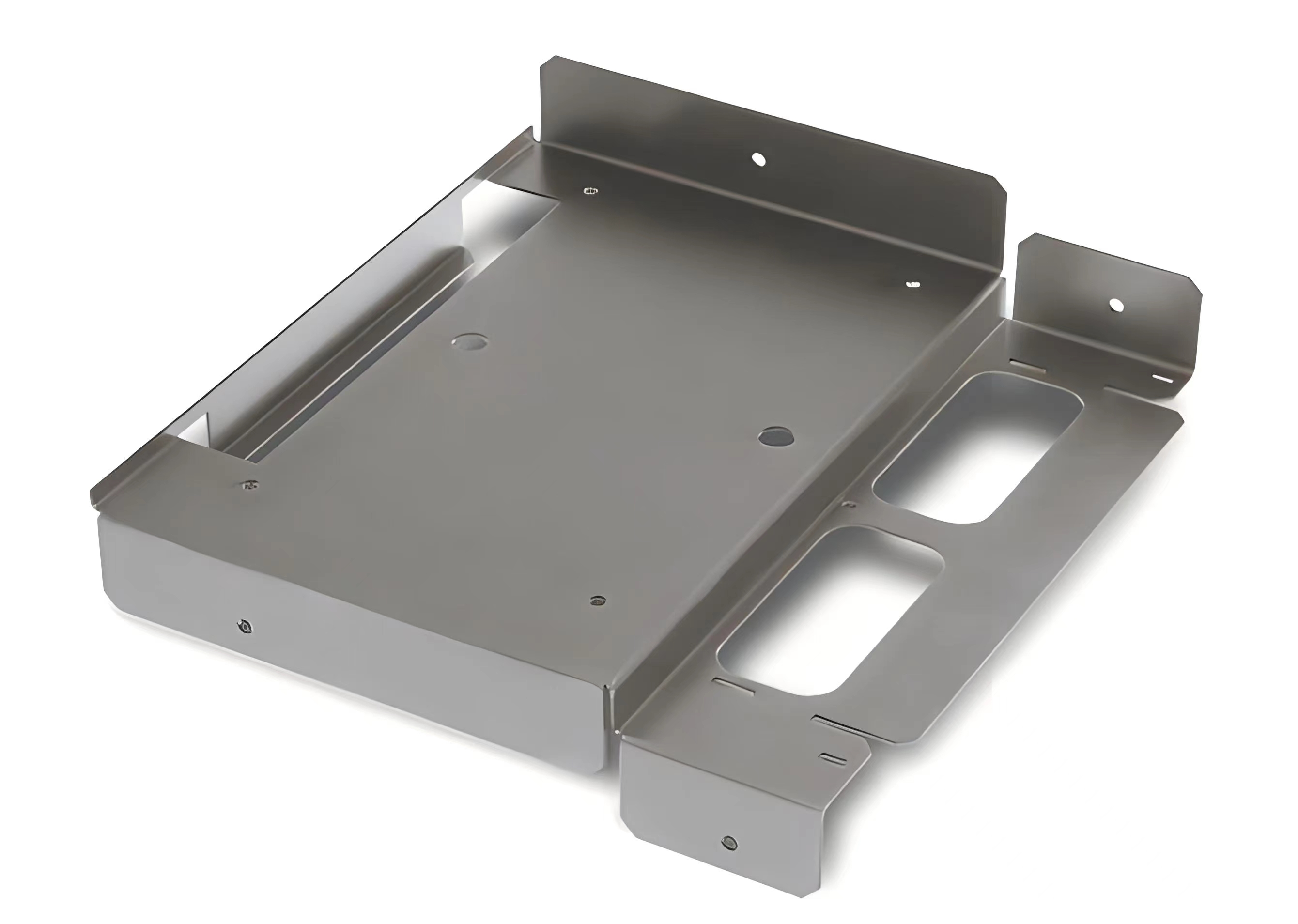

Introduction to Sheet Metal Fabrication

Sheet metal fabrication is a process that utilizes metal sheets to produce various metal components and parts through processes such as cutting, bending, forming, and welding. Below are the general steps involved in sheet metal fabrication:

Design: The first step in sheet metal fabrication is design, determining the dimensions, shape, and material of the required components. This involves using CAD (Computer-Aided Design) software to create component drawings and plan the manufacturing process.

Material Selection: Choose the appropriate metal sheet, commonly including steel, stainless steel, aluminum, etc. The selected material should meet the requirements of the components, such as strength and corrosion resistance.

Metal Cutting: Utilize cutting tools such as shearing machines, laser cutting machines, plasma cutting machines, etc., to cut the metal sheet into the desired shapes and dimensions. This is a fundamental step in the manufacturing process, and the precision of cutting directly influences the quality of the final product.

This image is sourced from the internet.

Metal Bending: Use a bending machine to bend the metal sheet according to design requirements, creating the three-dimensional structure of the components. Bending is achieved by applying pressure to the metal sheet, causing it to bend without breaking.

This image is sourced from the internet.

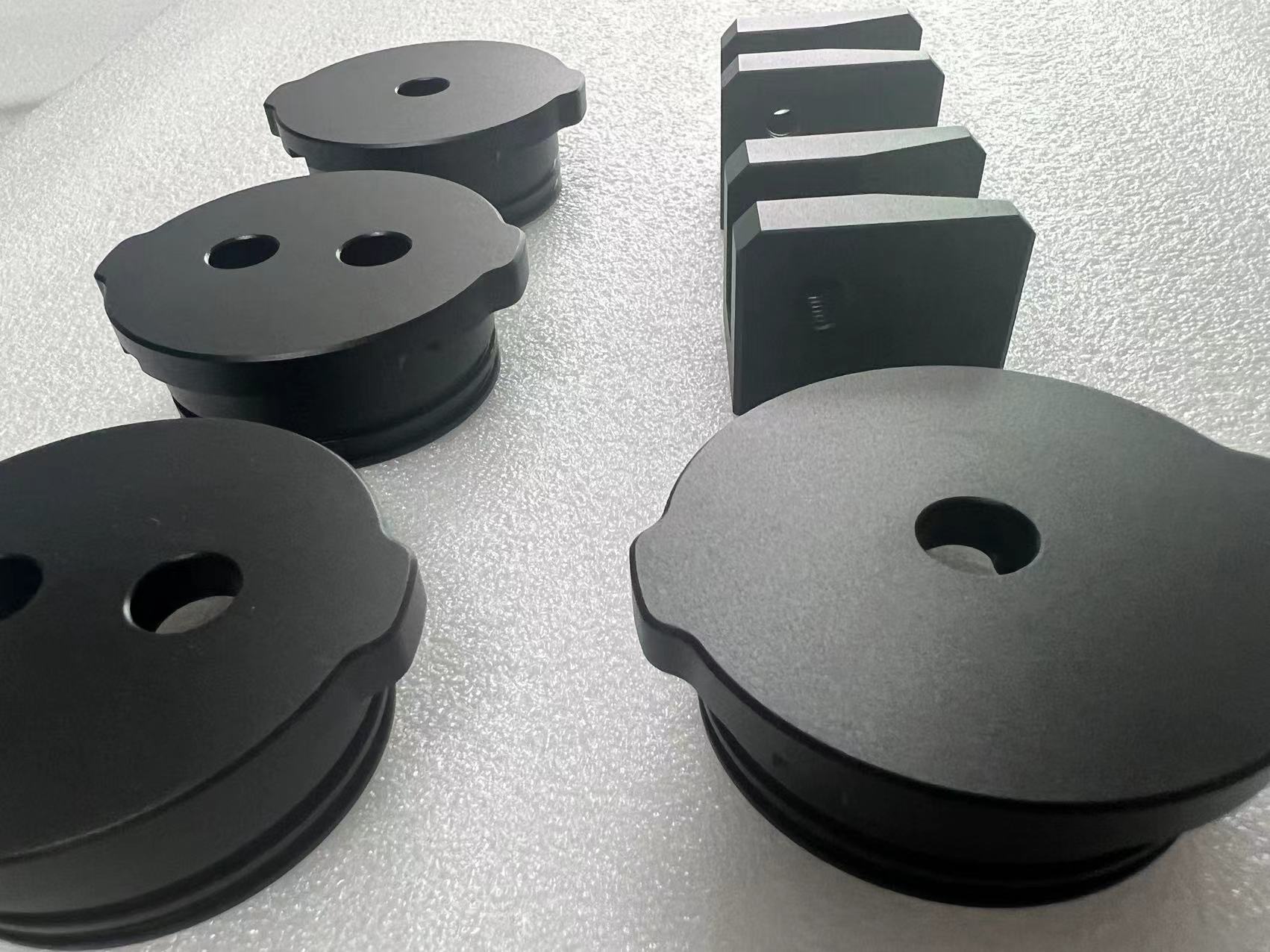

Forming:Employ forming tools and molds to shape the metal sheet, obtaining the desired curves, holes, or other specific shapes.

Metal Welding: In sheet metal fabrication, different components often need to be joined. This can be achieved through methods such as welding, riveting, bolt connections, etc. Welding involves melting the metal parts to bond them together.

This image is sourced from the internet.

Surface Treatment: Depending on the requirements, perform surface treatments on the sheet metal products, such as painting, electroplating, galvanizing, etc., to enhance corrosion resistance and improve aesthetic quality.

Assembly: If necessary, assemble various components together to form the final product.

Quality Control: Conduct quality inspections to ensure that the manufactured products meet design specifications and standards.

Sheet metal fabrication methods can be adjusted based on specific projects and requirements. The sequence of steps and the use of different processes may vary. This manufacturing method is versatile and applicable to the production of various sizes and shapes of metal components, making it widely used in the manufacturing industry.

The Exquisite Craftsmanship of

The Exquisite Craftsmanship of

Our 3D Printing: A Brief Intr

Our 3D Printing: A Brief Intr

Ruiyi's Control of Mold Qualit

Ruiyi's Control of Mold Qualit

Reliable Mold Manufacturer | E

Reliable Mold Manufacturer | E