CNC Machining and 3D Printing: A Comprehensive Guide

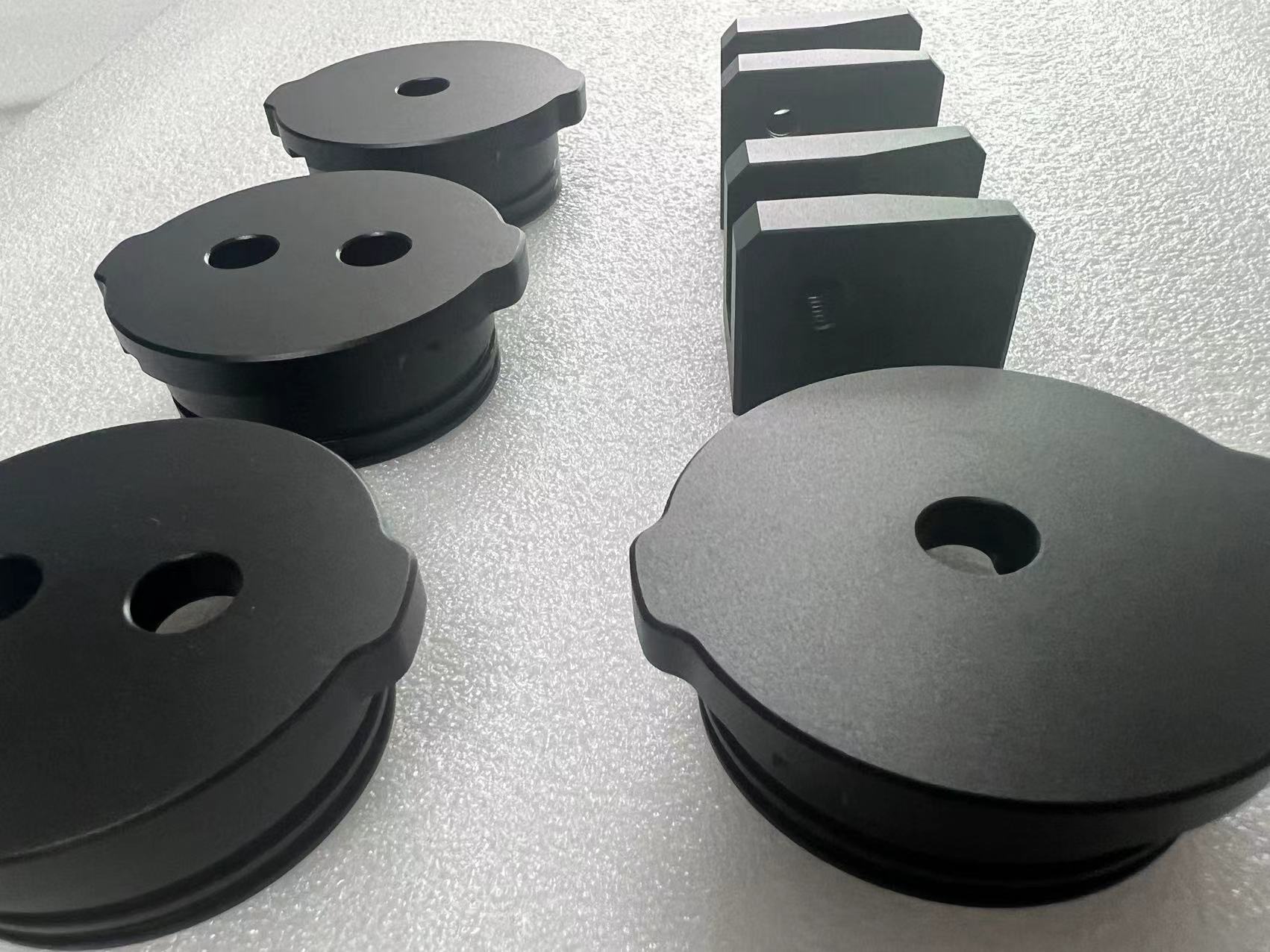

CNC ABS

The decision between CNC machining and 3D printing can significantly impact the outcome of your project.

Understanding the strengths and considerations of each process is crucial for making an informed choice tailored to your specific needs.

Material Selection:

CNC machining is suitable for a wide range of materials, including metals, plastics, and composites. It offers more material options compared to 3D printing.

3D printing works well with various plastics, metals, and some specialized materials. However, material selection might be more limited compared to CNC machining.

Precision and Tolerance:

CNC machining typically offers higher precision and tighter tolerances than 3D printing. If your product requires very tight tolerances or fine details, CNC machining may be the better choice.

Surface Finish:

CNC machining often produces smoother and more polished surfaces compared to 3D printing. If a high-quality surface finish is crucial for your application, CNC machining might be preferred.

Complexity of Geometry:

3D printing excels at creating complex geometric shapes, intricate designs, and internal structures that can be challenging or impossible to achieve with traditional machining methods.

CNC machining is better suited for products with simpler geometric shapes, especially if they involve precise cuts and well-defined features.

Production Volume:

CNC machining is generally more efficient for higher production volumes due to its faster production rates.

3D printing is often more cost-effective for low to medium production volumes, as it doesn't require tooling changes and setup time associated with CNC machining.

Cost Considerations:

For small production runs or prototypes, 3D printing might be more cost-effective due to lower setup costs and the ability to avoid tooling expenses.

CNC machining can become more cost-effective for larger production volumes.

Please note that 3D printing is typically priced based on weight. Therefore, for certain prototypes with larger volumes and greater weight, CNC machining is better.

Lead Time:

3D printing can have quicker lead times, especially for prototyping, as it doesn't require the creation of molds or tool changes.

CNC machining lead times may be longer due to setup and tooling requirements, but it can be faster for large production runs.

Strength and Durability:

CNC machined parts, especially when using metals, often exhibit higher strength and durability compared to 3D printed parts.

The mechanical properties of 3D printed parts can vary depending on the material used and the printing process.

In our tests, the toughness of certain plastic products is stronger when machined using CNC, making them less prone to brittle fractures even when subjected to high-altitude falls.

Conversely, the toughness of products produced through 3D printing is comparatively lower.

Ultimately, the decision between CNC machining and 3D printing depends on the specific requirements of your project, considering factors such as material, precision, complexity, production volume, cost, and lead time.

It's often beneficial to consult with our engineers or manufacturing experts to make an informed decision based on the unique characteristics of your product.

The Exquisite Craftsmanship of

The Exquisite Craftsmanship of

Our 3D Printing: A Brief Intr

Our 3D Printing: A Brief Intr

Ruiyi's Control of Mold Qualit

Ruiyi's Control of Mold Qualit

Reliable Mold Manufacturer | E

Reliable Mold Manufacturer | E