Surface Treatment for Sheet Metal Prototypes

Do you have any requirements regarding the surface treatment process for sheet metal prototypes?

Which factories in China are good for customizing sheet metal prototypes?

Are you familiar with the commonly used surface treatment processes for sheet metal prototypes?

How can surface treatment be implemented on sheet metal prototypes during processing?

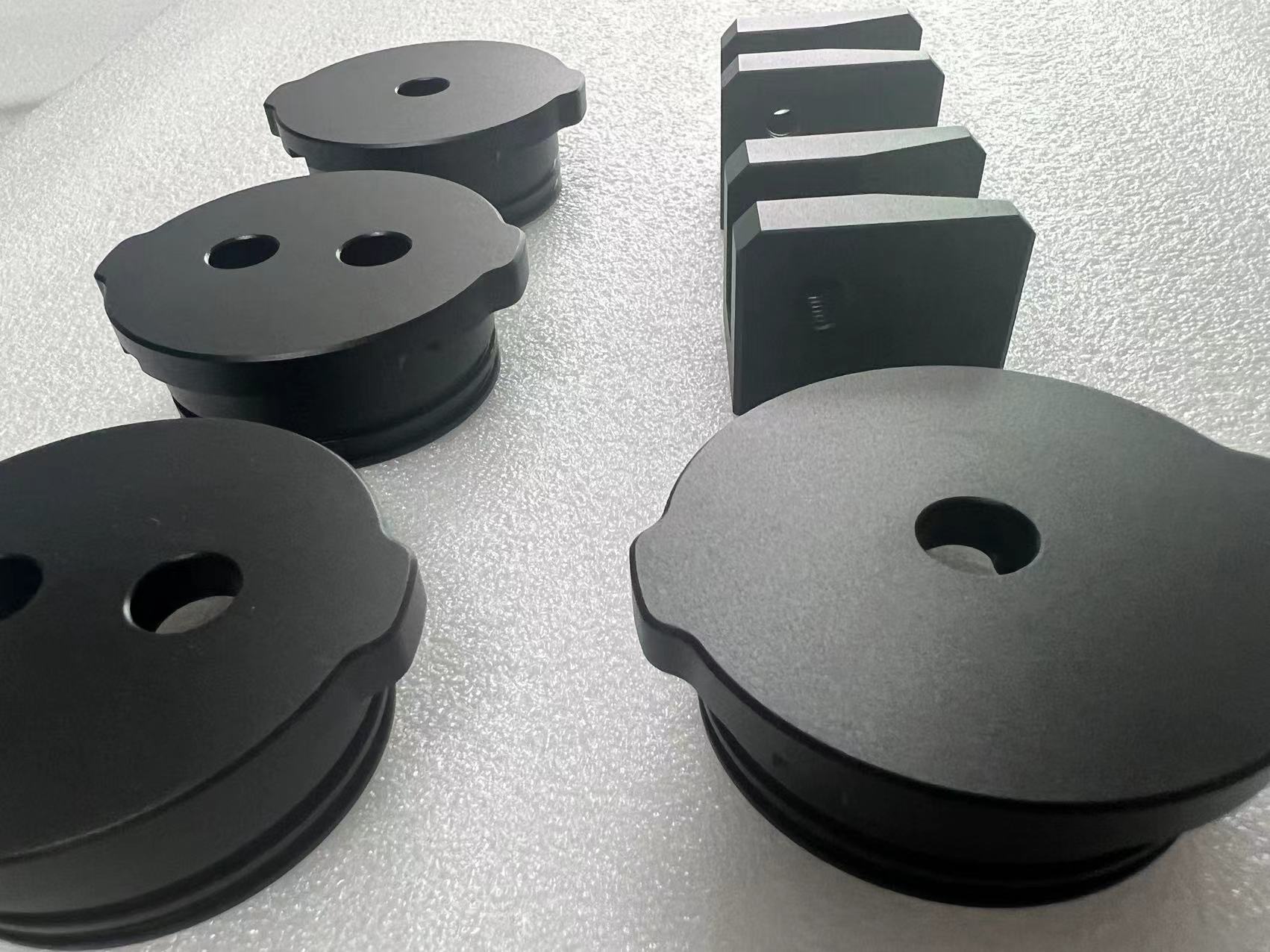

To help everyone better understand the sheet metal processing and surface treatment processes at Ruiyi,

below are some commonly used surface treatment processes for sheet metal processing: Spraying, Plating, Electrophoresis, Oxidation, etc.

Sheet Metal Prototype Spraying:

There are two types: paint spraying and powder coating.

After pretreating the material, use a spray gun and gas to apply the coating to the surface of the sheet metal workpiece, forming a coating layer on the surface of the workpiece.

After high-temperature baking and curing, it becomes a coating with different effects.

Sheet Metal Prototype Plating:

It is a technique that uses electrolysis to attach a layer of metal mold to the metal surface to prevent corrosion, improve wear resistance, conductivity, and provide a high-quality metallic appearance.

Galvanizing, colored zinc plating, white zinc plating, blue zinc plating, black zinc plating, nickel plating, chrome plating, etc.;

Sheet Metal Prototype Electrophoresis:

Mainly used for stainless steel, aluminum alloys, etc. It can present various colors and maintain the metallic luster of the product while improving surface performance.

It has good corrosion resistance.

There are other surface treatment methods for sheet metal prototypes: oxidation, chromate conversion coating, brushing, sandblasting, etc.

There are so many suppliers, how should you choose?

Ruiyi has a complete after-sales protection, support goods received before payment, reduce your procurement risk.

The Exquisite Craftsmanship of

The Exquisite Craftsmanship of

Our 3D Printing: A Brief Intr

Our 3D Printing: A Brief Intr

Ruiyi's Control of Mold Qualit

Ruiyi's Control of Mold Qualit

Reliable Mold Manufacturer | E

Reliable Mold Manufacturer | E