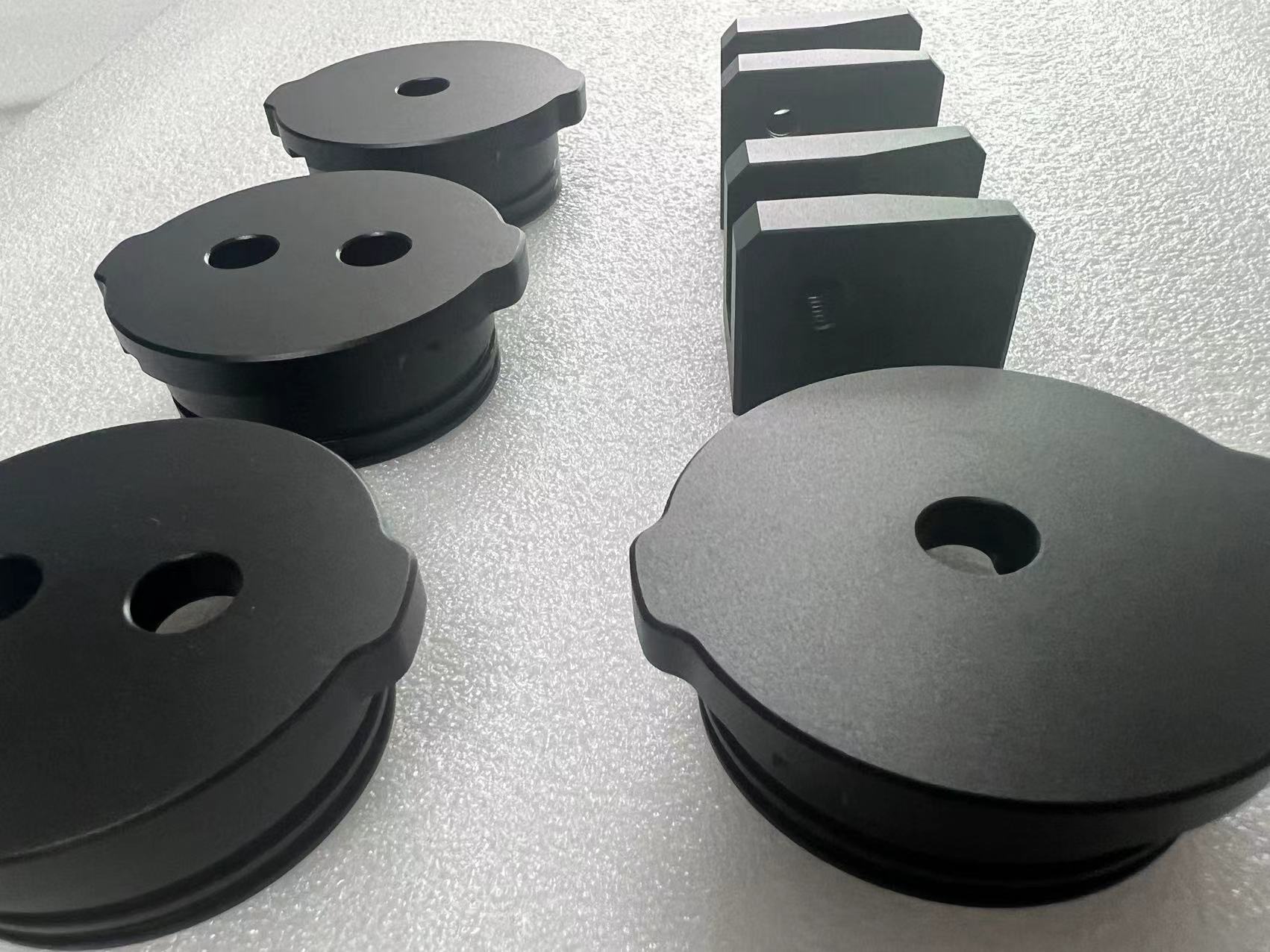

CNC Plastic Prototypes: Material & Surface Finish

What should be paid attention to in the manufacturing process?

For conventional product prototypes, ABS material is generally chosen, as it is easy to process and yields a nice finish.

For high-temperature resistant product prototypes, materials such as

(1) epoxy resin,

(2) electrical wood,

(3) black PC, and

(4) PA (nylon) can be used.

Except for black PC, which can be bonded, the other three materials cannot be bonded and require integral processing.

For wear-resistant product prototypes, POM or PA can be used.

Both of these materials cannot be bonded and require integral processing.

For high toughness product prototypes, PA or PP can be used.

Both of these materials cannot be bonded and require integral processing.

For transparent product prototypes, materials such as PMMA (acrylic), transparent ABS, and transparent PC can be used.

Prototypes made from these materials can achieve high transparency similar to real products through polishing.

Surface treatment of product prototypes generally includes spraying, electroplating, sandblasting, screen printing, pad printing, and other surface effects.

Spraying prototypes can yield glossy, matte, frosted, transparent, translucent, fluorescent, and other effects.

Feel free to check out our products for more examples and maybe we can help you take your project a step further.

The Exquisite Craftsmanship of

The Exquisite Craftsmanship of

Our 3D Printing: A Brief Intr

Our 3D Printing: A Brief Intr

Ruiyi's Control of Mold Qualit

Ruiyi's Control of Mold Qualit

Reliable Mold Manufacturer | E

Reliable Mold Manufacturer | E