Medical Device Manufacturing: Housing Prototyping | CNC& Sheet Metal

In medical equipment manufacturing, the need for swift prototyping and efficient production processes is paramount.

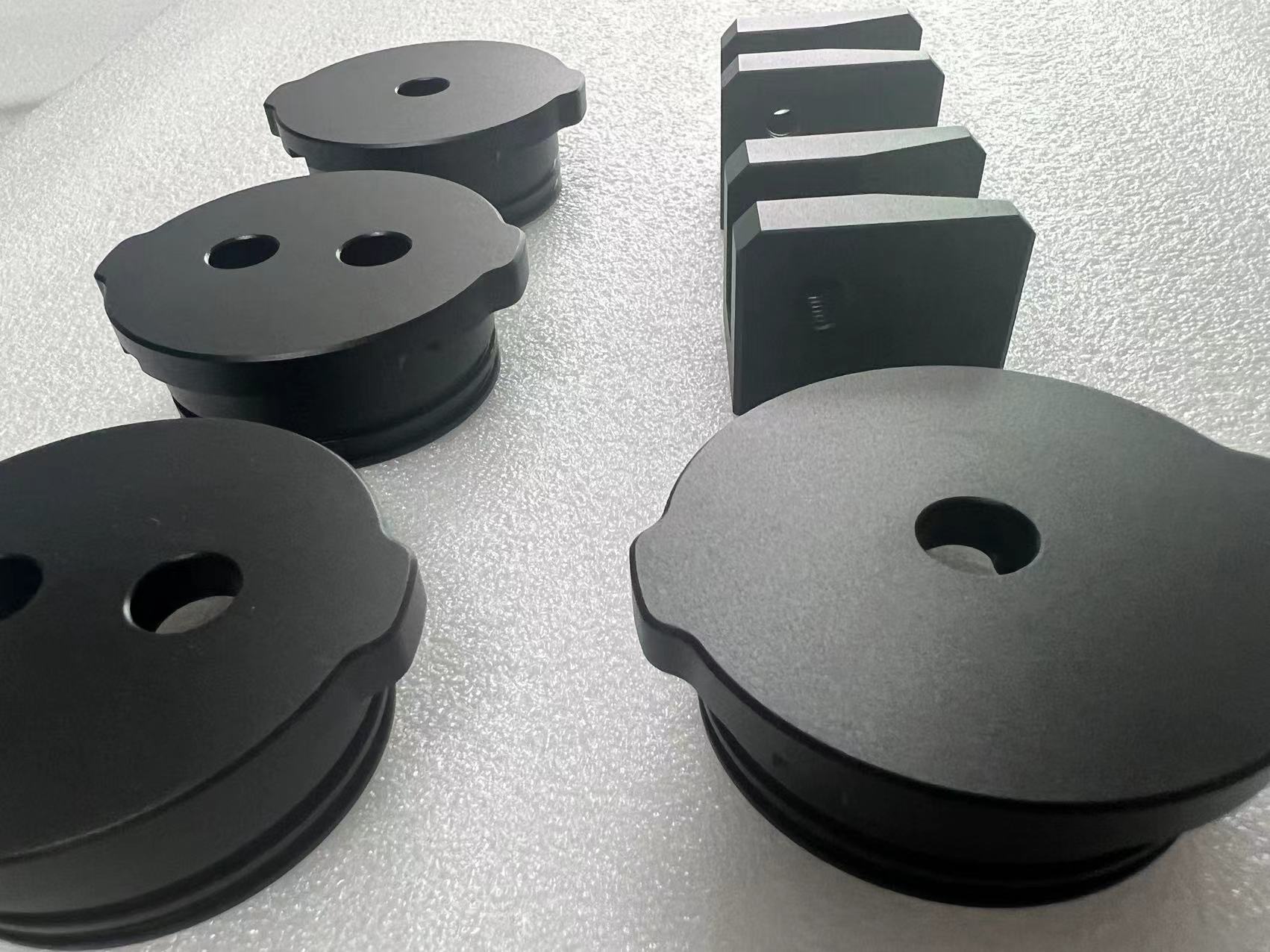

With advancements in technology, particularly in CNC machining and sheet metal fabrication, the medical industry is experiencing a revolution in the development of equipment housing and components.

Images from the Internet

Medical housing prototyping involves the creation of prototypes for the external casings of medical devices.

These prototypes serve crucial roles in product development, allowing for testing, refinement, and validation before mass production.

Rapid prototyping techniques enable manufacturers to swiftly iterate designs, accelerating the overall product development timeline.

Materials for Medical Device Manufacturing

Common materials used include various metals, such as aluminum, stainless steel, and titanium, as well as engineering plastics like ABS and PC (polycarbonate).

These materials offer properties such as durability, biocompatibility, and sterilizability, making them ideal for medical device housings.

Medical Device Manufacturing Equipment

In the production process of medical devices, manufacturing equipment plays a crucial role.

Common production equipment includes injection molding machines, CNC machine tools, and laser cutting machines, among others.

1. Injection molding machines are the primary equipment for manufacturing device housings and plastic components. They can rapidly manufacture product shapes by injecting molten material into molds.

2. CNC machine tools can perform high-precision machining, meeting the geometric shapes and size requirements of medical devices.

3. Laser cutting machines, on the other hand, can perform precise cutting and drilling operations, suitable for various materials.

Plastic Housing Surface treatment

Surface treatment methods for plastic housings include molding, drilling, deburring, cleaning, painting (silk-screening, printing), and electroplating.

Apart from ensuring non-toxic emissions and compliance with RoHS standards, meeting structural durability requirements when necessary, other aspects of plastic treatment methods are similar to general practices.

Image from the Internet

Our business covers many production items in the medical equipment category, which can help you get more exquisite products and realize profit benefits.

Welcome to contact us for quotation.

Shenzhen Ruiyi Model Technology Co., Ltd

The Exquisite Craftsmanship of

The Exquisite Craftsmanship of

Our 3D Printing: A Brief Intr

Our 3D Printing: A Brief Intr

Ruiyi's Control of Mold Qualit

Ruiyi's Control of Mold Qualit

Reliable Mold Manufacturer | E

Reliable Mold Manufacturer | E