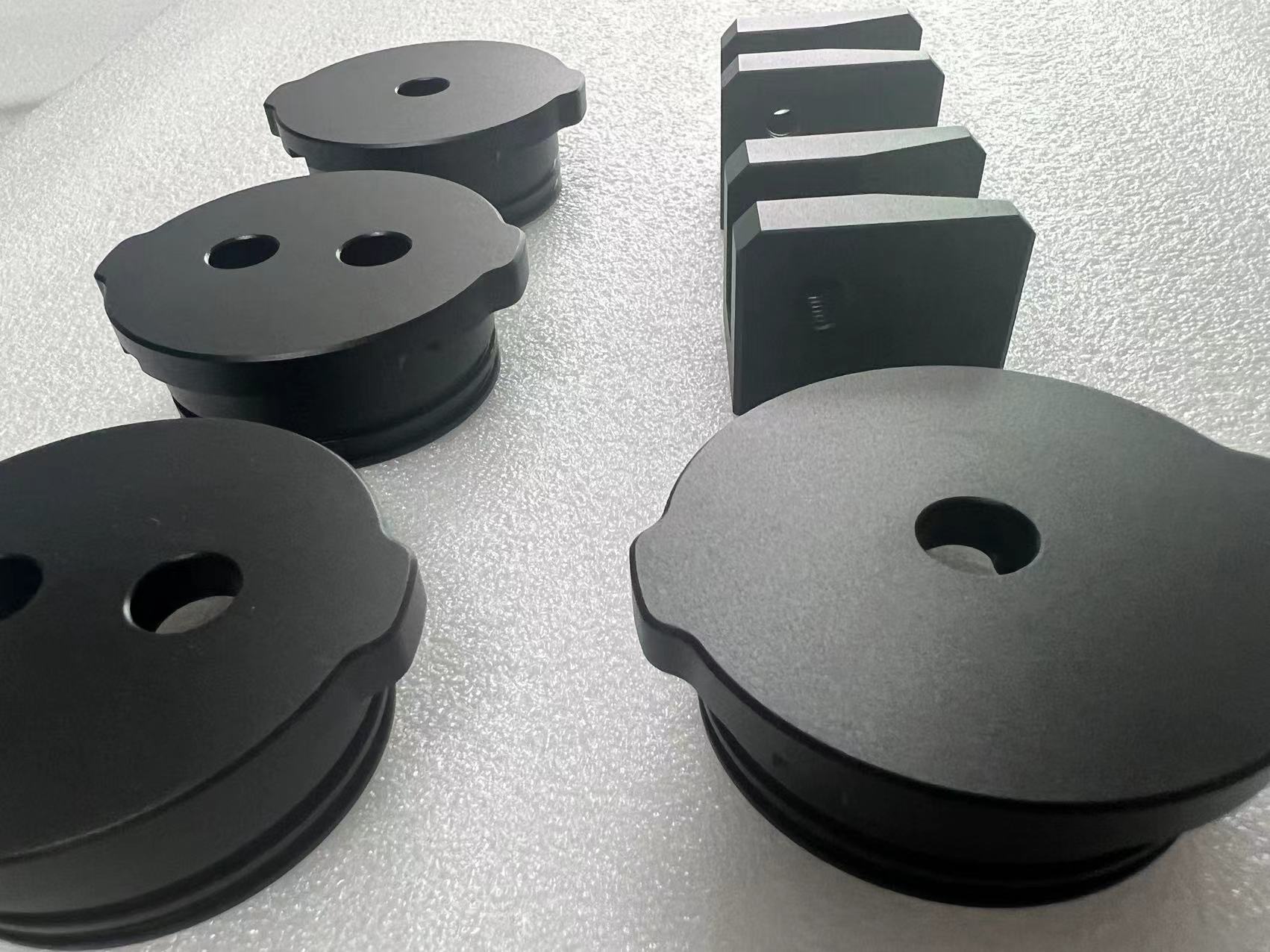

Vacuum Casting Prototype Models | Small Batch Production

Vacuum Casting, a manufacturing process specifically used for making prototype models and small batch reproductions.

Craft Costs: Machining Costs (Low), Unit Costs (Medium)

Typical Products:

Prototype models, electronic consumer goods, sports equipment, toys, etc.

Suitable Output:

Suitable for custom-made single pieces and small batch production.

Vacuum Casting: A craft specialized in producing delicate prototype models and small batch reproductions, widely used for previewing injection molded products.

Common plastics used in vacuum casting include PP and PA, with high flexibility in color selection and strength of molded parts, making it very suitable for product designers for prototype customization.

Design Recommendations:

Consider the volume of the product during the design process (it is recommended that the weight of a single part be within 2.5kg), as larger products will have a higher proportion of cooling shrinkage and longer production time when using vacuum casting for prototype production.

Try to avoid sharp product shapes as much as possible.

Pros and Cons of CNC Machining & Vacuum Molding:

Vacuum molding can produce all complex parts or designs in one go, while CNC machining requires production to be split according to size and structure.

Silicone rubber shrinks upon curing, which is a normal phenomenon. Once cured, it affects the molecular density of the silicone liquid.

The product shrinks like silicone rubber.

The shrinkage rate of high-quality silicone rubber is 1% to 3%, which affects tolerances, making CNC technology a better choice.

If you have a project, feel free to contact us for a quote, we do it in 1 day.

The Exquisite Craftsmanship of

The Exquisite Craftsmanship of

Our 3D Printing: A Brief Intr

Our 3D Printing: A Brief Intr

Ruiyi's Control of Mold Qualit

Ruiyi's Control of Mold Qualit

Reliable Mold Manufacturer | E

Reliable Mold Manufacturer | E