Prevent Rusting During Stainless Steel Processing | RUIYI MODEL

Why Does Stainless Steel Rust?

Although it's called stainless steel, being rust-free is its essence.

Stainless steel rusts because the metal ions (iron ions) on its surface come into contact with oxidants, such as oxygen in the air or humid environments.

These factors cause oxidation reactions of iron ions on the surface of stainless steel, leading to rust.

Generally, raw materials such as stainless steel plates and coils are difficult to rust because their passive film on the surface is intact, providing excellent corrosion resistance.

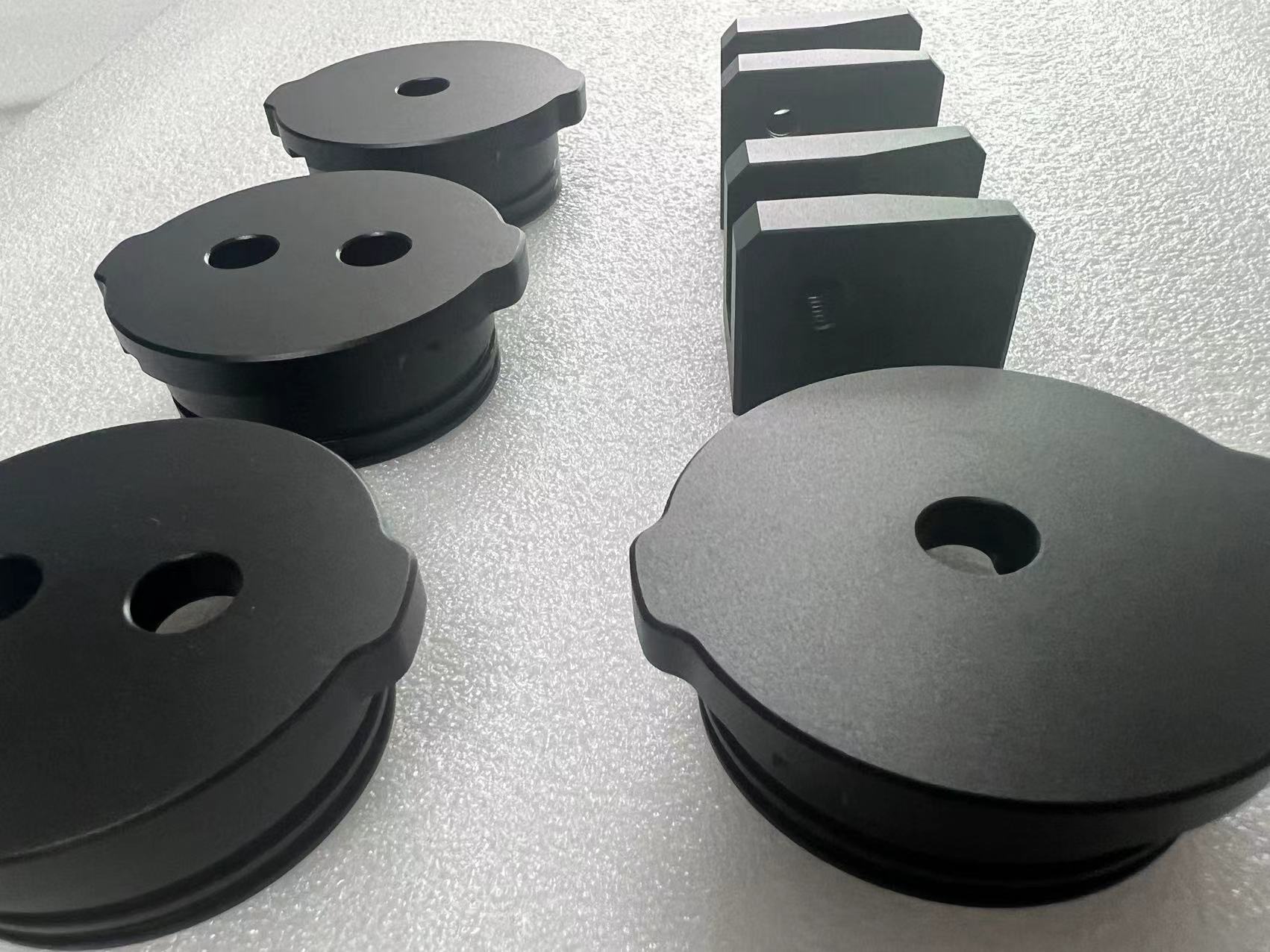

However, after processes like CNC machining such as turning, cutting, stamping, milling, etc., the passive film on the surface is damaged, or iron ions adhere to the mold, making it prone to rust.

How to Prevent Rusting During Stainless Steel Processing?

To prevent stainless steel from rusting, the following measures should be taken:

1. During processing, avoid exposing the surface of stainless steel to oxidants, acidic environments, humid environments, high salt environments, etc., as much as possible.

2. After processing is completed, promptly clean the surface of stainless steel to remove surface oxides.

3. Apply rust preventive oil on the surface of stainless steel to prevent the intrusion of oxidants.

4. High-end stainless steel products should undergo pickling passivation or natural passivation to improve their corresponding corrosion resistance and rust prevention levels.

The Exquisite Craftsmanship of

The Exquisite Craftsmanship of

Our 3D Printing: A Brief Intr

Our 3D Printing: A Brief Intr

Ruiyi's Control of Mold Qualit

Ruiyi's Control of Mold Qualit

Reliable Mold Manufacturer | E

Reliable Mold Manufacturer | E