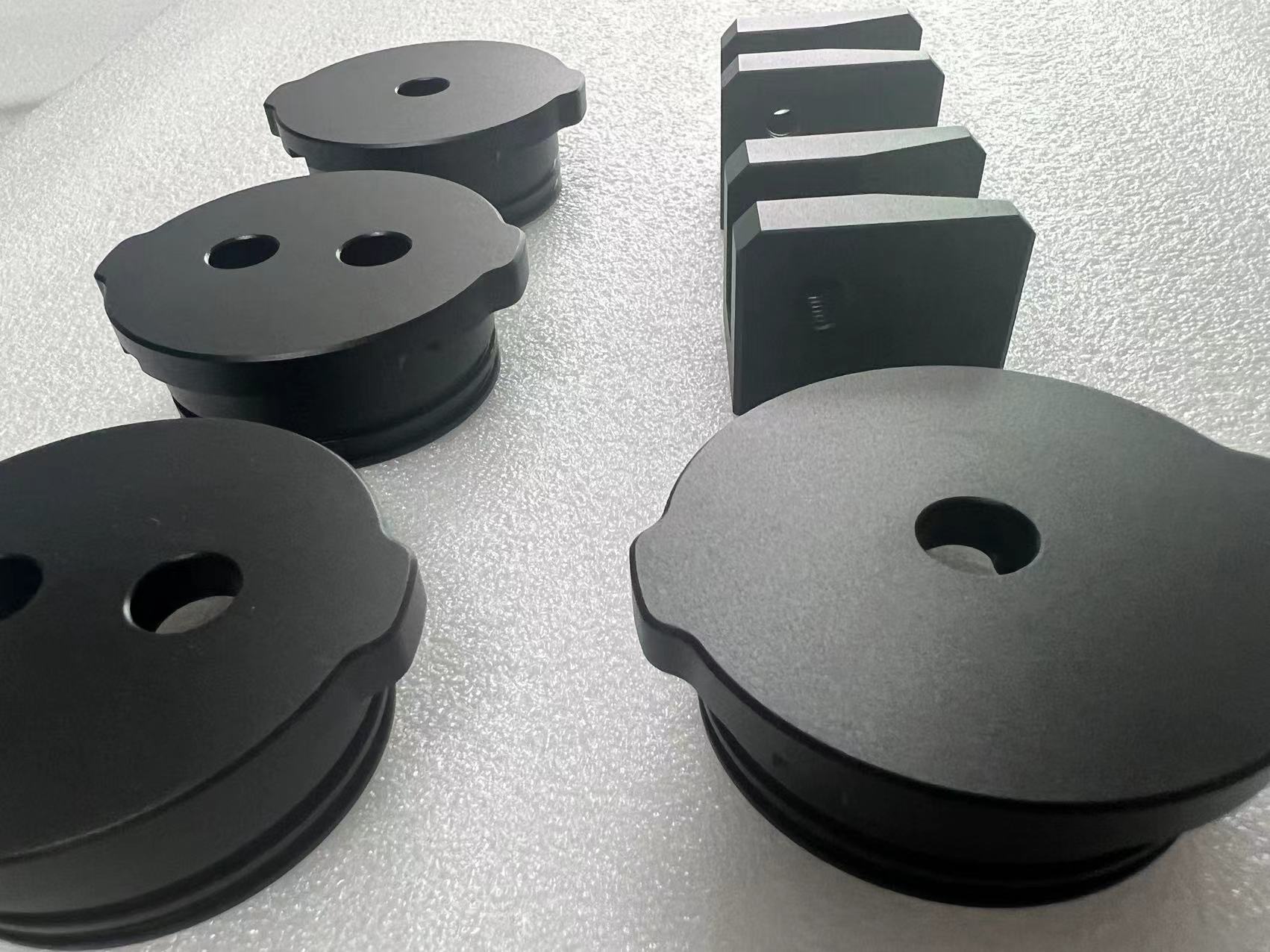

CNC-Machined ABS Parts | Cost-Effective Solution

From prototype development to full-scale production, CNC machining of ABS presents a cost-effective alternative, eliminating the need for expensive molds and streamlining the production process.

ABS CNC machining provides a spectrum of secondary processing options tailored to meet diverse manufacturing needs.

Whether it's drilling, tapping, threading, or milling, CNC technology offers precise and consistent results, ensuring the seamless integration of intricate features into ABS components.

This flexibility empowers manufacturers to iterate designs rapidly, facilitating efficient prototyping and accelerating time-to-market.

Surface Finishing Selections:

Beyond functionality, aesthetics play a crucial role in the success of a product.

ABS CNC machining offers a plethora of surface finishing selections to enhance the visual appeal and tactile experience of components.

From sanding and polishing to painting and plating, CNC-machined ABS parts can achieve a myriad of finishes, ranging from smooth and glossy to textured and matte.

This versatility allows manufacturers to customize the appearance of their products to align with brand identity and consumer preferences, fostering market competitiveness and brand loyalty.

Cost-Effective Solution:

One of the most compelling advantages of ABS CNC machining is its cost-effectiveness.

Traditional manufacturing methods often necessitate the creation of costly molds, especially for low-volume or complex designs.

In contrast, CNC machining bypasses this constraint by directly fabricating parts from CAD models, eliminating the need for tooling expenses.

This cost-saving feature makes ABS CNC machining an attractive option for both prototyping and production, enabling manufacturers to allocate resources efficiently and optimize their bottom line.

Assembly of Finished Products:

In addition to machining individual components, ABS CNC machining facilitates the seamless assembly of finished products.

With precise dimensional accuracy and repeatability, CNC-machined parts ensure compatibility and ease of assembly, minimizing downtime and streamlining the production process.

This integrated approach enables manufacturers to deliver high-quality products consistently, meeting market demand and surpassing customer expectations.

In conclusion, ABS CNC machining emerges as a game-changing solution for manufacturers seeking efficiency, precision, and versatility in secondary processing and surface finishing.

From concept to assembly, ABS CNC machining revolutionizes the manufacturing journey, unlocking new possibilities and driving industry advancement.

The Exquisite Craftsmanship of

The Exquisite Craftsmanship of

Our 3D Printing: A Brief Intr

Our 3D Printing: A Brief Intr

Ruiyi's Control of Mold Qualit

Ruiyi's Control of Mold Qualit

Reliable Mold Manufacturer | E

Reliable Mold Manufacturer | E