CNC Plastic Machining / Online CNC Quoting

CNC Plastic Machining:

Leading the way as a future invisible champion, its superior precision machining capabilities and high production efficiency have permeated various aspects of our lives.

What exactly is the allure of CNC plastic machining? Let's explore the unique insights and original high-level knowledge in this field.

The Mystery of CNC Plastic Machining

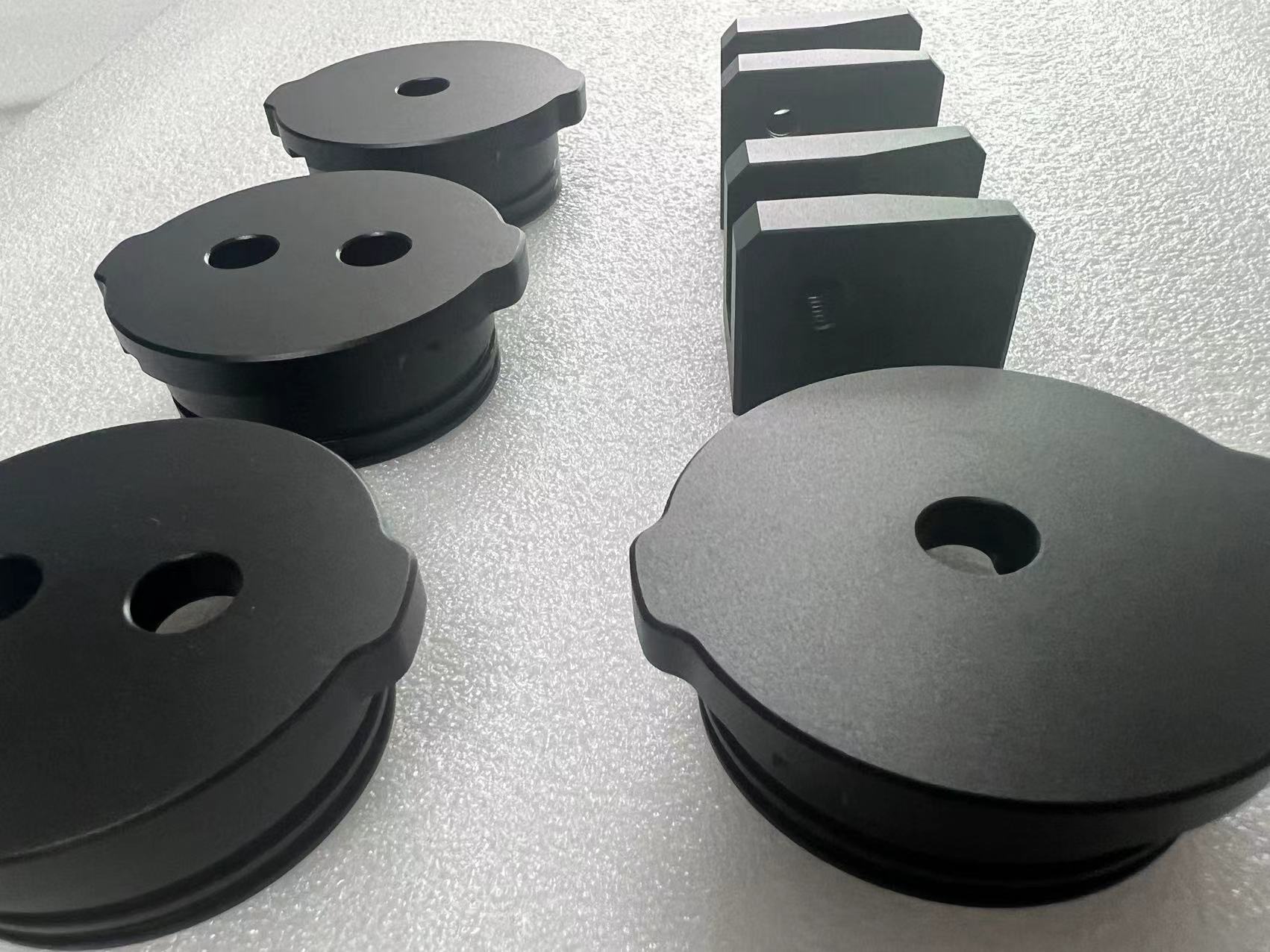

CNC plastic machining utilizes computer-controlled high-speed rotating tools to precisely cut, carve, polish, and process plastic materials to meet product design requirements.

The development of this technology has achieved significant results, becoming an important force driving the transformation and upgrading of the manufacturing industry.

Applications of CNC Plastic Machining in Popular Fields

- Aerospace

With the rapid development of aerospace industries worldwide, the demand for material performance and machining accuracy is increasing.

The application of CNC plastic machining technology in the aerospace field provides strong support for the preparation of high-performance composite materials.

For example, aircraft interior parts, satellite antennas, unmanned aerial vehicle fuselages, etc., all rely on the support of CNC plastic machining technology.

- Medical Equipment

Medical equipment requires high precision and material quality, and CNC plastic machining technology plays an important role in medical equipment manufacturing.

Devices such as pacemakers, artificial joints, endoscopes, etc., require precision manufacturing using CNC plastic machining technology.

- 3D Printing

3D printing technology has gained much attention in recent years, and CNC plastic machining serves as an important complement to 3D printing.

In the manufacturing of complex structures, CNC plastic machining technology can achieve higher precision and better surface quality.

Additionally, CNC plastic machining can also be used in the manufacturing of 3D printers, supporting the development of 3D printing technology.

Innovations and Breakthroughs in CNC Plastic Machining Technology

- Five-Axis Linkage Technology

Traditional CNC plastic machining technology generally involves three-axis linkage, while five-axis linkage technology can achieve higher machining precision and complexity.

The application of five-axis linkage technology in fields such as aerospace and medical equipment provides possibilities for the manufacturing of complex parts.

- High-Speed Machining Technology

High-speed machining technology can greatly improve production efficiency while ensuring machining quality.

Through continuous innovation in tool materials, machining processes, etc., CNC plastic machining technology has achieved significant results in the field of high-speed machining.

- Intelligent Machining Technology

With the development of artificial intelligence, big data, and other technologies, CNC plastic machining is moving towards intelligence.

By introducing intelligent control systems to achieve automation and digitization of the machining process, production efficiency and machining quality can be improved.

The Exquisite Craftsmanship of

The Exquisite Craftsmanship of

Our 3D Printing: A Brief Intr

Our 3D Printing: A Brief Intr

Ruiyi's Control of Mold Qualit

Ruiyi's Control of Mold Qualit

Reliable Mold Manufacturer | E

Reliable Mold Manufacturer | E