Mass Production Machining of Precision Parts: Building High-Quality Manufacturing Services

In modern industry, mass production and precision machining of precision parts have become the core competitiveness of the manufacturing industry.

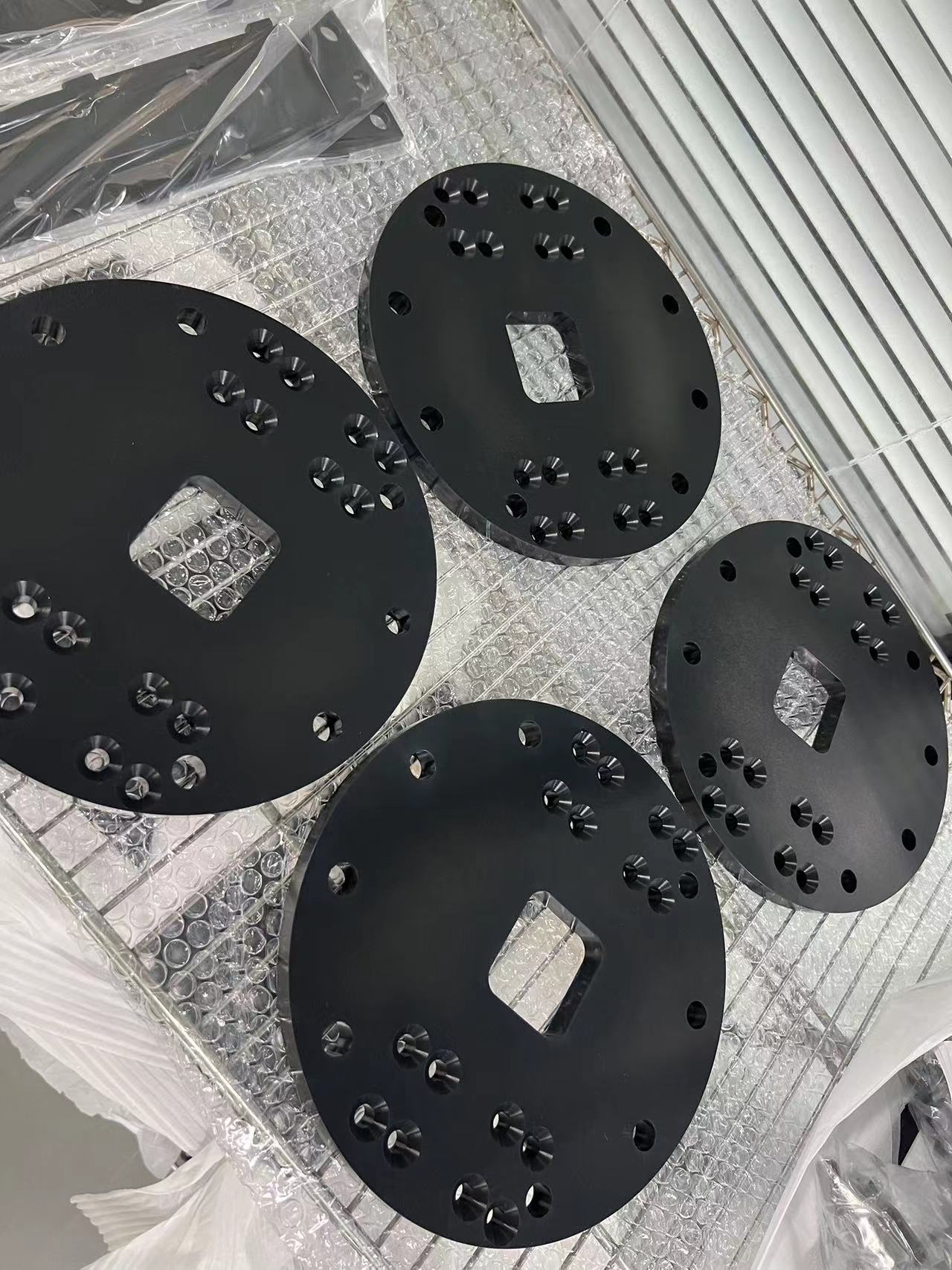

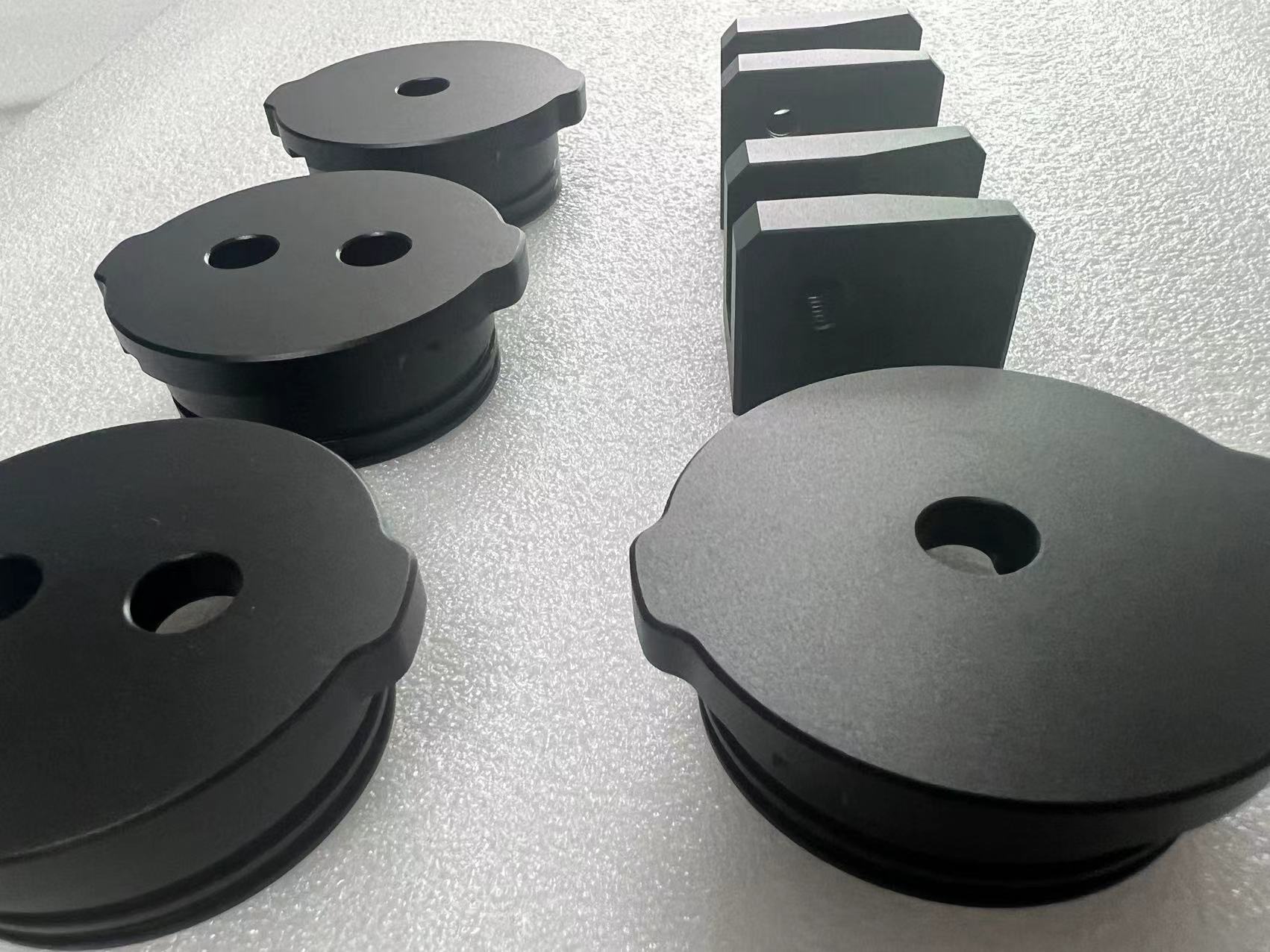

Precision machining is a key technology that enables the production of high-quality precision parts, while mass production machining efficiently assists major enterprises in meeting production needs.

It is widely used in mechanical, electronic, aerospace, and other fields.

In this vibrant sector, breaking through technological limits and the future development of manufacturing have become urgent issues for us to address.

This article will provide you with a detailed understanding of the importance and development trends in this field.

I. Challenges and Opportunities of Mass Production Machining

1. Challenges

(1) Production Efficiency:

Improving production efficiency while ensuring product quality is the primary challenge faced by mass production machining.

As order volumes increase, achieving efficient and stable production while reducing costs has become the focus of attention for enterprises.

(2) Talent Cultivation:

Mass production machining requires a large number of skilled talents, yet the current talent cultivation system in China's manufacturing industry is still imperfect, resulting in a shortage of skilled talents, which affects production efficiency and product quality.

(3) Technological Innovation:

With the intensification of market competition, enterprises need to continuously innovate technologically to increase product added value to meet customer demands. However, technological innovation requires significant investment in funds and manpower, imposing high demands on the research and development capabilities of enterprises.

2. Opportunities

(1) Policy Support:

The Chinese government attaches great importance to the development of the manufacturing industry and has introduced a series of policy measures to provide a favorable development environment for mass production machining.

(2) Market Demand:

With the continuous growth of the national economy, both domestic and international markets have shown increasing demand for mass production machining, providing broad development space for the manufacturing industry.

(3) Industrial Upgrading:

China's manufacturing industry is facing the task of transforming from low-end manufacturing to mid-to-high-end manufacturing.

Mass production machining helps improve the global competitiveness of China's manufacturing industry.

II. Technological Breakthroughs in Precision Machining Parts

1. Precision CNC Machining Technology

Precision CNC machining technology is one of the core technologies for precision machining parts.

By using high-precision CNC equipment combined with advanced CNC programming technology and processes, high-precision and efficient machining of parts can be achieved.

In addition, the use of five-axis linked CNC machining technology can further improve machining accuracy and complexity.

2. High-Speed Machining Technology

High-speed machining technology is a technique that increases cutting speed and reduces cutting thickness to achieve efficient and high-precision machining while ensuring machining quality.

High-speed machining can reduce production costs, improve production efficiency, and enhance the surface quality of parts.

3. Additive Manufacturing Technology

Additive manufacturing technology (3D printing) is an emerging manufacturing technology that achieves the three-dimensional forming of parts by layer-by-layer material deposition.

Additive manufacturing technology has the advantages of flexible design, short manufacturing cycles, and high raw material utilization rate, which helps realize mass production of complex parts.

4. Robotics Technology

The application of robotics technology in the manufacturing industry can improve the level of production automation and achieve mass production machining.

Through the collaborative operation of robots and CNC equipment, intelligent and networked machining processes can be realized, thereby improving production efficiency and product quality.

![]()

Mass production plays a significant positive role in the development of modern industry and the improvement of modern living standards.

Since our establishment, our company has adhered to the development philosophy of high quality and high efficiency.

Relying on years of accumulated production capacity and experience, we continuously break through technological limits and are willing to work with new and old customers to create value together, sincerely cooperating for mutual success.

The Exquisite Craftsmanship of

The Exquisite Craftsmanship of

Our 3D Printing: A Brief Intr

Our 3D Printing: A Brief Intr

Ruiyi's Control of Mold Qualit

Ruiyi's Control of Mold Qualit

Reliable Mold Manufacturer | E

Reliable Mold Manufacturer | E