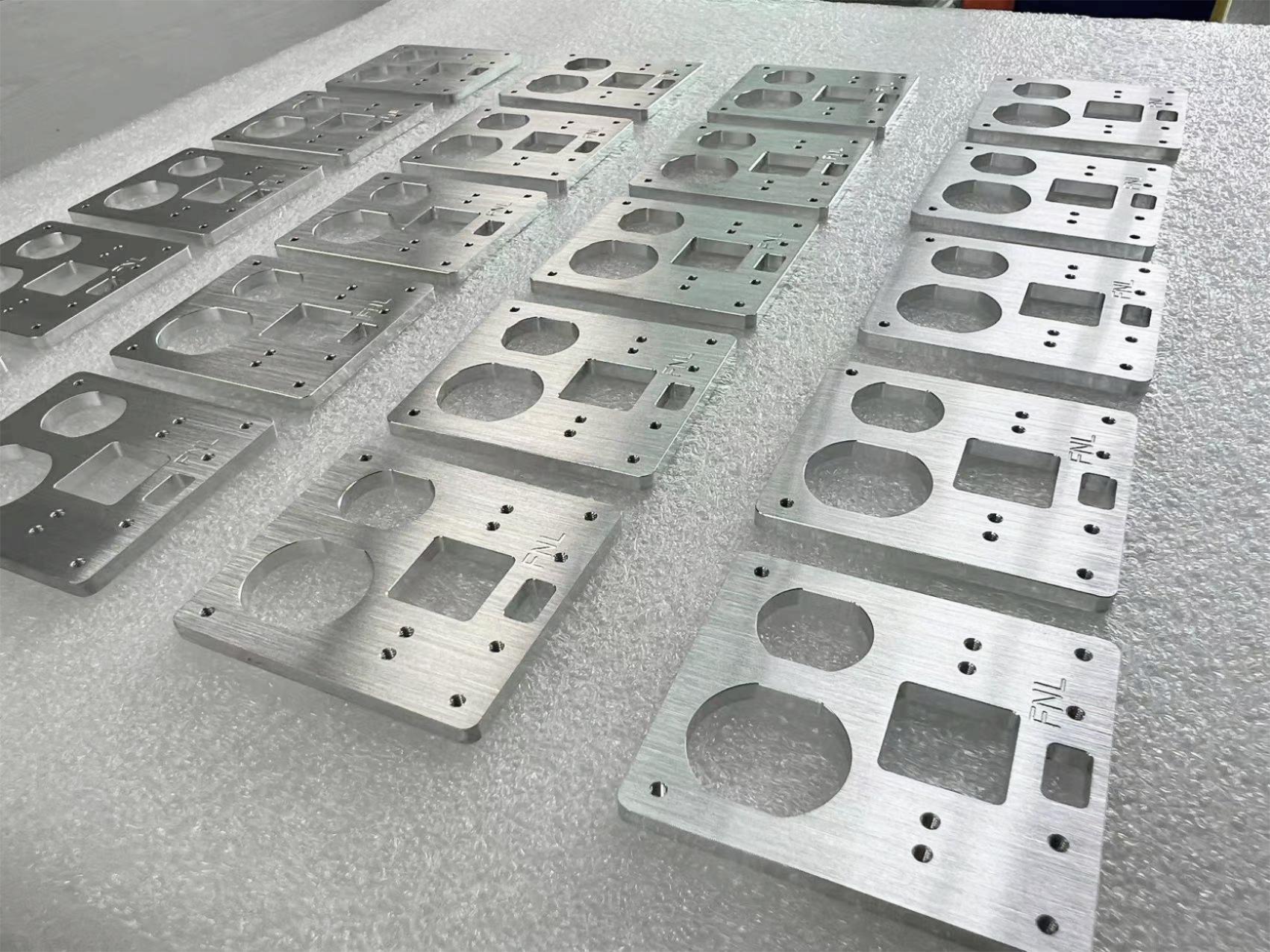

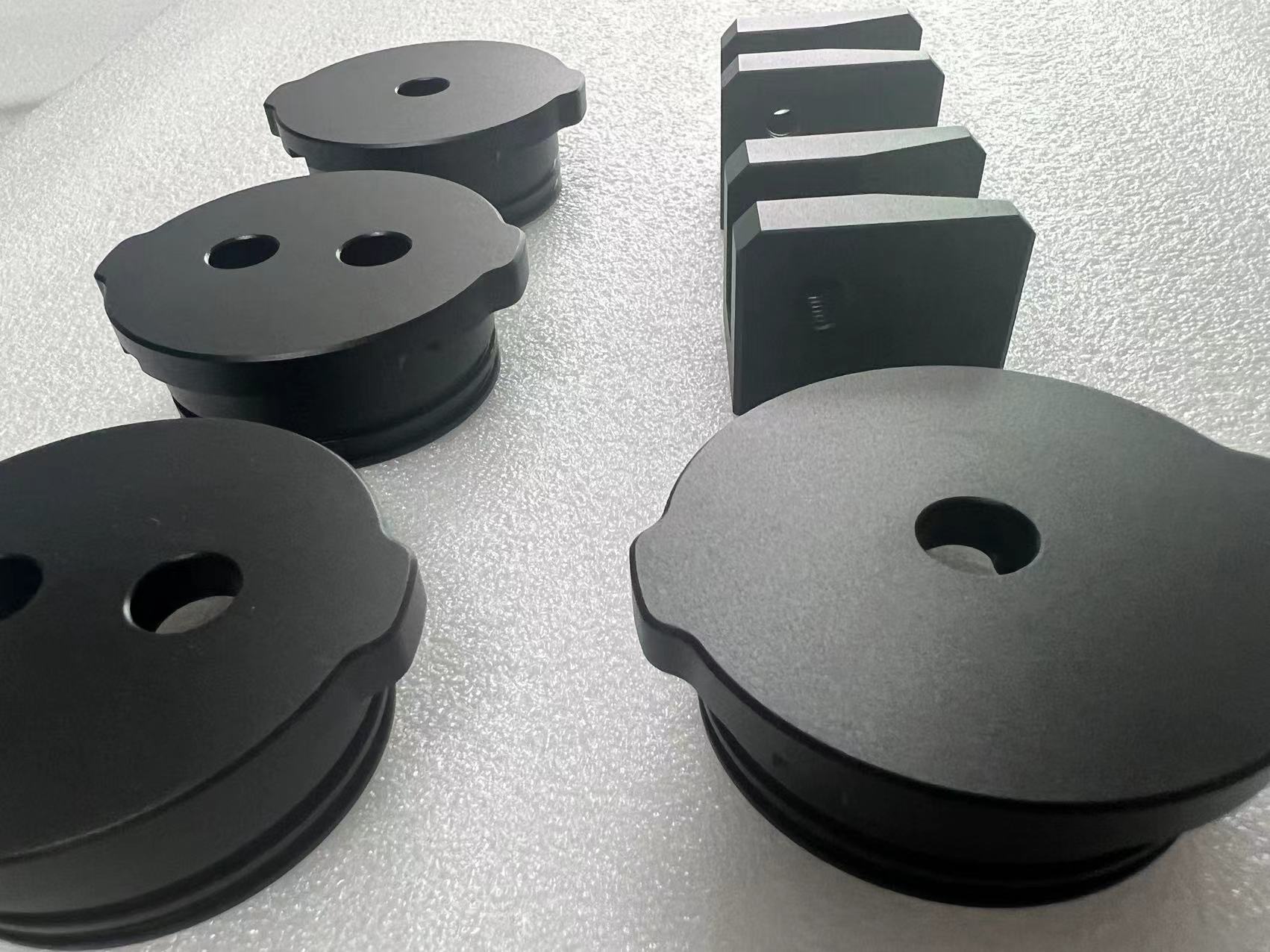

Made in China, Aluminum Part Processing: The Rising New Force in Manufacturing

As a developed manufacturing country, China's manufacturing industry has developed rapidly, and 'Made in China' is widely recognized globally.

Aluminum parts processing, as an important part of China's manufacturing industry, has also received extensive attention and application.

Aluminum parts processing, Made in China, has become a bright business card for the global manufacturing industry.

I. Definition and Classification of Aluminum Parts Processing

Aluminum parts processing, as the name suggests, refers to the process of using aluminum as the main raw material and employing various mechanical processing methods to give it specific shapes, sizes, and properties.

Aluminum parts processing mainly includes casting, extrusion, stretching, stamping, bending, welding, surface treatment, and other processes.

Aluminum parts are widely used in aerospace, automotive, construction, electronics, packaging, and other fields.

II. Current Situation of Aluminum Parts Processing in China

Currently, China has become the world's largest production base for aluminum parts processing, with a vast industrial chain and complete infrastructure.

According to relevant data, the output value of China's aluminum parts processing industry accounts for more than half of the global total output value.

In addition, there are numerous aluminum parts processing enterprises in China, distributed in various provinces, forming regional competitive advantages.

III. Future Development Trends of China's Aluminum Parts Processing Industry

1. High-end Development:

With the continuous improvement of China's technological level, the aluminum parts processing industry will expand into high-end fields such as aerospace and new energy vehicles.

2. Green Development:

The strengthening of environmental awareness is driving the aluminum parts processing industry towards green and low-carbon development.

Recycling aluminum resources, reducing energy consumption and pollution in the production process have become important trends in the industry's development.

3. Intelligent Manufacturing:

The introduction of intelligent manufacturing technology will make the production process of aluminum parts processing more efficient and precise.

Automation, digitization, and networking will become new features of industry development.

4. Cluster Development:

The aluminum parts processing industry will present a trend of clustered development, with enterprises strengthening cooperation to form a pattern of collaborative innovation and common development in the upstream and downstream of the industrial chain.

IV. Application Fields of Aluminum Parts Processing

1. Aerospace:

Lightweight and high-strength aluminum alloys are used to manufacture ships, satellites, missiles, etc., reducing overall weight and improving flight and navigation efficiency.

2. Automotive Manufacturing:

Aluminum alloys are used to manufacture automotive components, significantly reducing vehicle weight, improving fuel economy, and performance.

3. Construction:

Aluminum alloys are used to manufacture doors, windows, curtain walls, ensuring strength, reducing weight, and having good corrosion resistance and easy cleaning characteristics.

4. Home Appliances:

Aluminum alloys are used to manufacture various electrical appliances such as refrigerators, ovens, washing machines, air conditioners, improving product performance and appearance.

5. Electronics:

Aluminum alloys are used to manufacture electronic products such as smartphones, tablets, cameras, improving product portability and heat dissipation.

Shenzhen Ruiyi Model Technology Co., Ltd. specializes in the processing and manufacturing of various precision instrument parts, with its own factory and advanced large-scale processing equipment.

It has become one of the trusted suppliers in the relevant mechanical processing industry.

The Exquisite Craftsmanship of

The Exquisite Craftsmanship of

Our 3D Printing: A Brief Intr

Our 3D Printing: A Brief Intr

Ruiyi's Control of Mold Qualit

Ruiyi's Control of Mold Qualit

Reliable Mold Manufacturer | E

Reliable Mold Manufacturer | E