The Advantages of CNC Machining in Rapid Prototyping and Low volume Manufacturing

In the fast-paced world of manufacturing, CNC machining stands out as a powerhouse, offering unmatched benefits in rapid prototyping and low-volume manufacturing.

Let's delve into the key advantages that make CNC machining the go-to solution for those seeking precision, speed, and cost-effectiveness in their production processes.

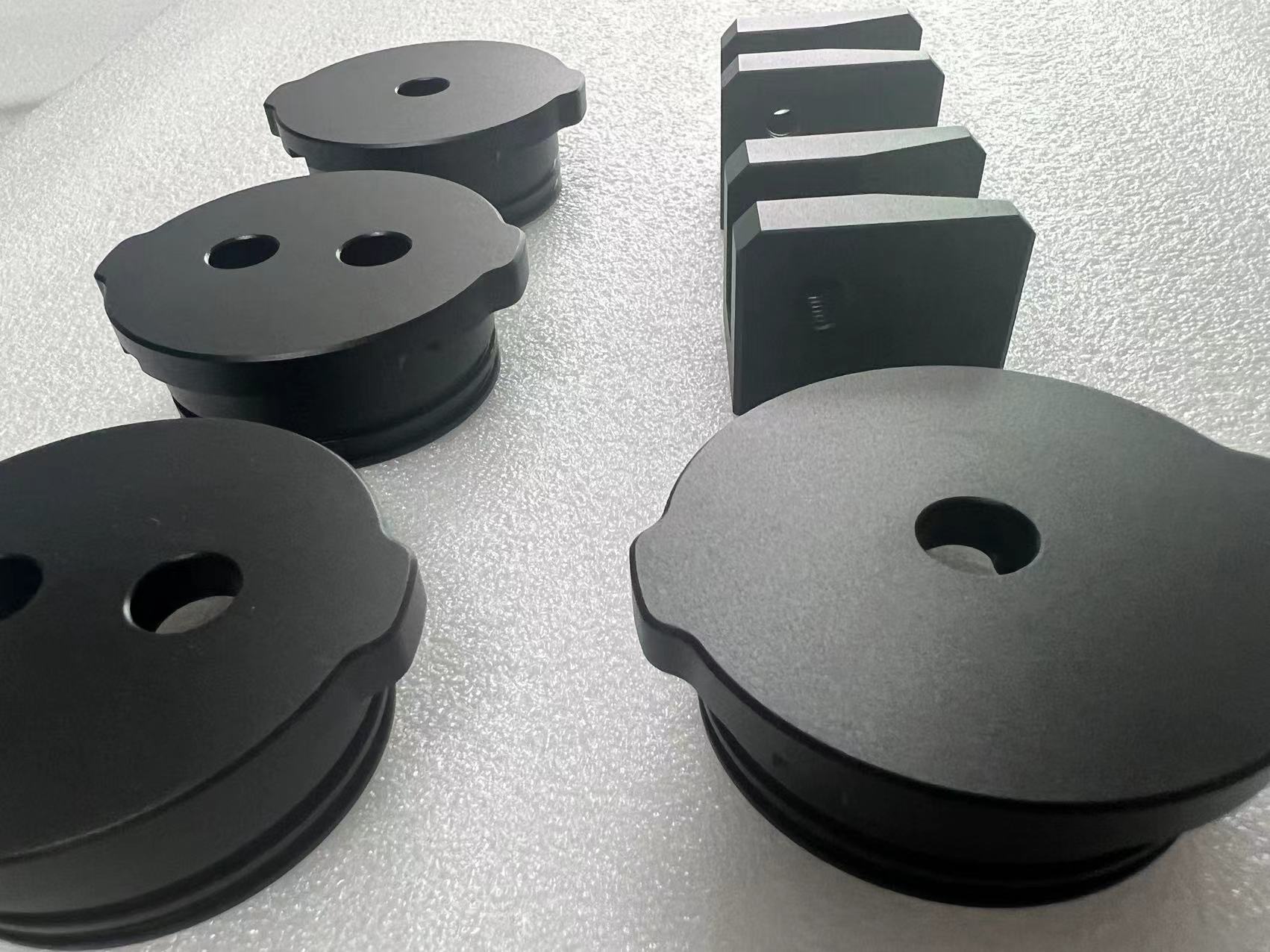

This image is sourced from the internet.

Precision in Rapid Prototyping:

CNC machining takes center stage in rapid prototyping, providing a dynamic and precise solution for transforming design concepts into tangible prototypes.

With its computer-controlled accuracy, intricate designs and complex geometries are effortlessly brought to life.

Explore the world of precision where every detail matters, ensuring your prototypes meet the highest standards.

Cost-Effective Low-Volume Manufacturing:

Traditional manufacturing methods often incur substantial mold costs, particularly for smaller production volumes.

When completing prototype designs, customers may need 10 pieces, 5 pieces, or even just 1 piece for verification and testing.

CNC machining eliminates the constraints of mold costs, becoming an economically efficient choice.

Its flexibility not only lowers startup costs but also provides customers with the ability to make design changes and adapt quickly to market demand fluctuations.

Through CNC machining, businesses can optimize resource utilization, achieving cost optimization and enhanced competitiveness.

Material Diversity:

CNC machining can effectively process a variety of materials, minimizing waste and reducing overall costs.

During the prototype design phase, customers may be uncertain about materials. Choosing an efficient CNC factory allows customers to use different materials for processing through rapid prototyping, testing the most suitable material and appearance color for the product.

Additionally, precise cutting and shaping capabilities contribute to sustainable and economical production processes.

Speed and Scalability:

In today's fiercely competitive market, time is crucial.

CNC machining ensures rapid turnaround times, enabling factories to meet urgent deadlines without compromising quality.

Prototyping can be completed in as fast as 3 days.

The controllability of production time makes it an ideal choice to adapt to changing production requirements and meet customer demands without sacrificing efficiency.

This rapid response capability not only provides flexibility for businesses but also offers significant assistance in maintaining a competitive advantage in the market.

In conclusion, adopting CNC machining provides a strategic advantage for customers and businesses aiming to balance precision, speed, and cost-effectiveness in prototype design and production runs. The advantages of CNC machining in rapid prototyping and low-volume manufacturing are undeniable.

The Exquisite Craftsmanship of

The Exquisite Craftsmanship of

Our 3D Printing: A Brief Intr

Our 3D Printing: A Brief Intr

Ruiyi's Control of Mold Qualit

Ruiyi's Control of Mold Qualit

Reliable Mold Manufacturer | E

Reliable Mold Manufacturer | E