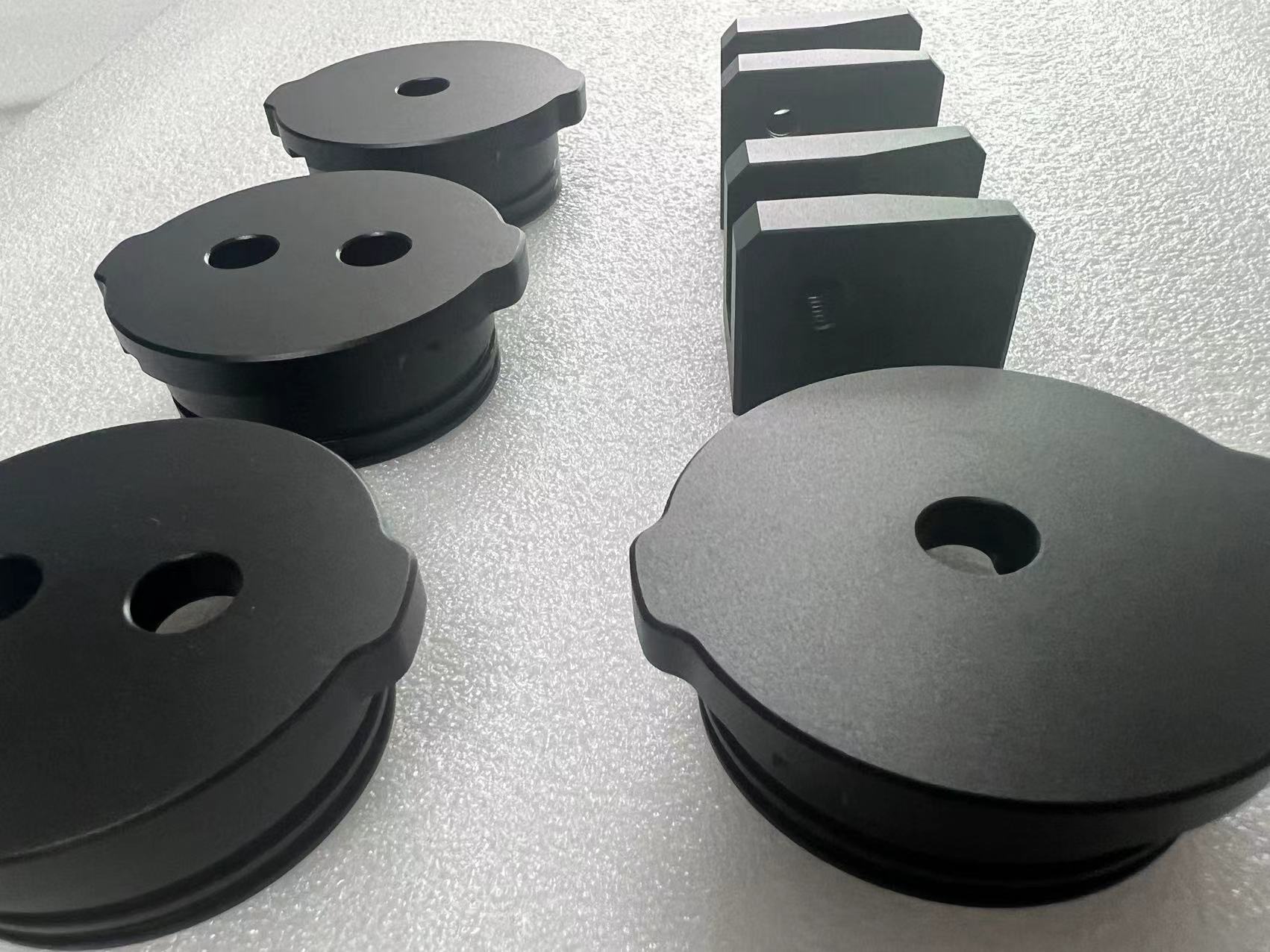

Injection Molding Material Selection

This image is sourced from the internet.

Choosing the right mold material for injection molding is crucial for the success of the manufacturing process and the quality of the final product. Several factors should be considered when selecting the mold material:

Type of Plastic Resin:

Different plastic resins have varying processing temperatures, shrinkage rates, and abrasiveness. Choose a mold material that is compatible with the specific plastic resin you intend to use for injection molding.

Mold Temperature:

Consider the required mold temperature for the plastic resin. Some materials may require higher or lower temperatures for proper molding. Common mold materials include tool steel, pre-hardened steel, and aluminum, each with its temperature capabilities.

Production Volume:

The expected production volume influences the choice of mold material. For high-volume production, durable materials like tool steel may be preferred, while aluminum might be suitable for low to medium production volumes due to its quicker cooling and shorter cycle times.

Cost Considerations:

The cost of mold materials varies significantly. While tool steel offers high durability, it is more expensive than aluminum. Consider your budget constraints and weigh the cost against the expected production volume and product requirements.

Mold Complexity:

The complexity of the mold design also plays a role in material selection. More intricate molds may benefit from materials with better machinability and wear resistance. Tool steels are often chosen for complex molds due to their high hardness.

Mold Machinability:

Consider the ease with which the mold material can be machined. Some materials are easier to machine than others, impacting the manufacturing process's efficiency and lead times.

Surface Finish Requirements:

The surface finish of the mold directly affects the final product's appearance. If a smooth surface finish is crucial, select a mold material that allows for precision machining and polishing.

Corrosion Resistance:

Consider the environment and conditions in which the injection molding will take place. If the mold is exposed to corrosive substances, choose a material with good corrosion resistance.

Cycle Time and Heat Dissipation:

Different materials have varying thermal conductivity, affecting the mold's ability to dissipate heat during the injection molding process.

This can impact cycle times and overall efficiency.

Common mold materials include:

Tool Steel (e.g., P20, H13): Durable and suitable for high-volume production.

Pre-hardened Steel (e.g., 420SS): Offers good machinability and moderate durability.

Aluminum: Lightweight, faster heat dissipation, suitable for prototyping and low to medium production volumes.

In summary, the choice of mold material for injection molding involves a careful consideration of factors such as the type of plastic resin, mold temperature, production volume, cost, mold complexity, machinability, surface finish requirements, corrosion resistance, and heat dissipation. It's advisable to consult with our mold designers, engineers, and material experts to make an informed decision based on the specific requirements of your project.

The Exquisite Craftsmanship of

The Exquisite Craftsmanship of

Our 3D Printing: A Brief Intr

Our 3D Printing: A Brief Intr

Ruiyi's Control of Mold Qualit

Ruiyi's Control of Mold Qualit

Reliable Mold Manufacturer | E

Reliable Mold Manufacturer | E